2027-35-B vs B88069X1790C103

| Part Number |

|

|

| Category | Gas Discharge Tube Arresters (GDT) | Gas Discharge Tube Arresters (GDT) |

| Manufacturer | Bourns Inc. | EPCOS (TDK) |

| Description | GDT 350V 15% 10KA THROUGH HOLE | GDT 230V 15% 5KA |

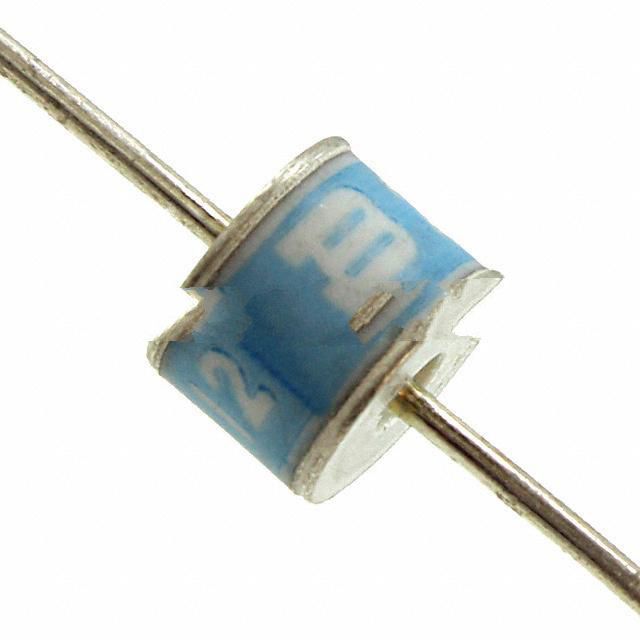

| Package | Axial Cylinder | Cylinder No Lead |

| Series | 2027 | EC230XN |

| Mounting Type | Through Hole | User Defined |

| Package / Case | Axial Cylinder | Cylinder No Lead |

| Tolerance | ±15% | ±15% |

| Number of Poles | 2 | 2 |

| Voltage - DC Spark Over (Nom) | 350V | 230V |

| Impulse Discharge Current (8/20µs) | 10000A (10kA) | 5000A (5kA) |

| Fail Short | No | No |

-

1. What is a gas discharge tube arrester?

A gas discharge tube arrester is a device that uses the principle of gas discharge to achieve overvoltage protection. It is mainly composed of a ceramic sealed discharge tube, which contains two or more metal electrodes with gaps and is filled with inert gas such as argon or neon. When the external voltage exceeds the breakdown voltage of the discharge tube, the gas in the tube is ionized under the action of the electric field to form a conductive channel, which quickly discharges the large current and high voltage generated by the lightning strike, thereby protecting the subsequent circuit from damage. Once the overvoltage disappears, the discharge tube will return to a high-resistance insulation state, waiting for the next impact.

-

2. What is a GDT gas discharge tube?

A GDT gas discharge tube (Gas Discharge Tube) is a device used to protect electronic equipment from transient voltage damage. It is mainly composed of one or more discharge gaps, sealed in a ceramic cavity or glass tube filled with inert gas. Under normal working conditions, the GDT maintains a high resistance state; when the voltage exceeds its breakdown voltage, the gas in the gas discharge tube is ionized to form a conductive path, which introduces the surge current into the ground, thereby protecting the equipment. Once the overvoltage disappears, the GDT returns to a high impedance state and waits for the next shock.

Working Principle

The working principle of GDT is based on the gas discharge phenomenon. Under normal operating voltage, the inert gas inside the GDT remains non-conductive and the device is in a high impedance state. When the voltage reaches or exceeds its breakdown voltage, the gas ionizes to form a plasma path, causing the GDT to present a low impedance state, directing the surge current into the ground, thereby protecting the device. After the overvoltage disappears, the GDT returns to a high impedance state. -

3. What is the difference between GDT and MOV?

GDT (gas discharge tube) and MOV (varistor) each have their own characteristics and applicable scenarios in circuit protection.

Working Principle and Characteristics

GDT: GDT is a switching overvoltage protection component with the characteristics of large flow rate, large inter-electrode insulation resistance, slow response speed and small parasitic capacitance. It is often used in high-frequency electronic circuit protection, especially as the first or second level protection in multi-level protection circuits. The working principle of GDT is to limit the voltage through gas discharge. When the voltage reaches a certain threshold, the gas in the gas discharge tube is ionized, thereby conducting the current and protecting the subsequent circuit.

MOV: MOV is a clamping type overvoltage protection component with large flow rate, slow response speed and large parasitic capacitance. MOV uses its nonlinear characteristics to clamp the voltage to a relatively fixed voltage value when overvoltage occurs, thereby protecting the subsequent circuit. The main materials of MOV are divalent element zinc and hexavalent element oxygen, and its nonlinear characteristics are used to limit the voltage. -

4. What are the advantages and disadvantages of GDT?

Advantages: before breakdown, it is equivalent to an open circuit, with high resistance and low leakage current; after breakdown, it can pass a large current with low voltage drop; the pulse flow rate is large, and the commonly used specifications are 2KA, 10KA, 20KA, etc., and the highest can reach more than 100KA; the junction capacitance is low, and most of them are less than 2pF.

Disadvantages: The response speed is slow, generally 0.2~0.3 microseconds, and the fastest is about 0.1 microseconds; the breakdown voltage consistency is poor, the dispersion is large, generally ±20%; the breakdown voltage has only a few specific values.