ADC12DL066CIVS/NOPB vs ADS8371IPFBT

| Part Number |

|

|

| Category | Data Acquisition - Analog to Digital Converters (ADC) | Data Acquisition - Analog to Digital Converters (ADC) |

| Manufacturer | Texas Instruments | Texas Instruments |

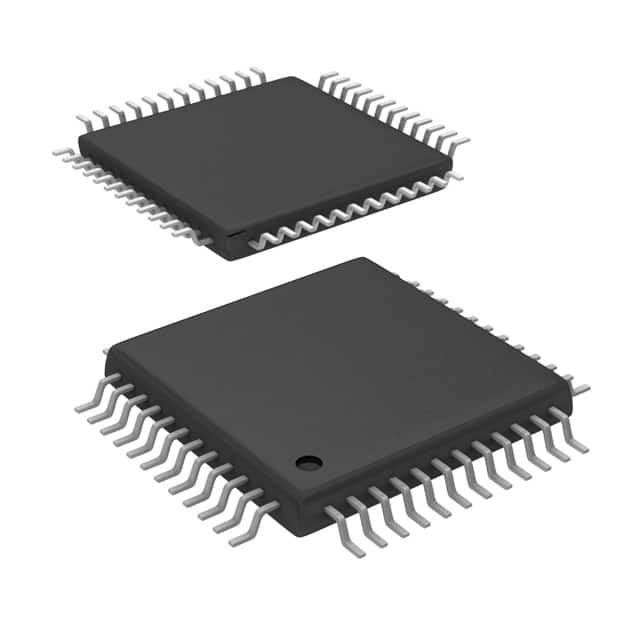

| Description | IC ADC 12BIT PIPELINED 64TQFP | IC ADC 16BIT SAR 48TQFP |

| Package | Tray | -Reel® |

| Series | - | microPOWER™ |

| Features | Simultaneous Sampling | - |

| Operating Temperature | -40°C ~ 85°C | -40°C ~ 85°C |

| Mounting Type | Surface Mount | Surface Mount |

| Package / Case | 64-TQFP | 48-TQFP |

| Supplier Device Package | 64-TQFP (10x10) | 48-TQFP (7x7) |

| Reference Type | External, Internal | External |

| Sampling Rate (Per Second) | 66M | 750k |

| Data Interface | Parallel | Parallel |

| Number of Bits | 12 | 16 |

| Voltage - Supply, Analog | 3V ~ 3.6V | 5V |

| Voltage - Supply, Digital | 2.4V ~ 3.6V | 2.7V ~ 5.25V |

| Number of Inputs | 2 | 1 |

| Input Type | Differential | Differential |

| Configuration | S/H-ADC | S/H-ADC |

| Ratio - S/H:ADC | 1:1 | 1:1 |

| Number of A/D Converters | 2 | 1 |

| Architecture | Pipelined | SAR |

-

1. What are DAC and ADC?

ADC and DAC are two important concepts in digital electronics. ADC stands for "analog-to-digital converter", which can convert analog signals into digital signals. DAC stands for "digital-to-analog converter", which can convert digital signals into analog signals. Both converters play an important role in many electronic products, such as mobile phones, televisions, stereos, etc.

-

2. What is analog data acquisition?

Analog data acquisition refers to the process of converting continuously changing signals of physical quantities into digital signals so that computers can process and record these signals. This process involves the use of an analog quantity collector, which is a hardware device that can convert analog signals of physical quantities into digital signals and then transmit them to a computer for processing and recording.

-

3. What process converts analog to digital?

There are three basic processes for analog to digital conversion:

The first process is "sampling", which is to extract the sample value of the analog signal at equal intervals to turn the continuous signal into a discrete signal.

The second process is called "quantization", which is to convert the extracted sample value into the closest digital value to represent the size of the extracted sample value.

The third process is "encoding", which is to represent the quantized value with a set of binary digits. After these three processes, the digitization of the analog signal can be completed. This method is called "pulse encoding".

After the digital signal is transmitted to the receiving end, a restoration process is required, that is, the received digital signal is converted back to an analog signal so that it can be understood by the receiver. This process is called "digital-to-analog conversion", which reproduces it as sound or image. -

4. How to convert analog to digital without ADC?

Analog to digital conversion without ADC can be achieved through PWM circuit. This method is suitable for those main control chips without built-in ADC, which needs to be solved by two GPIOs and an operational amplifier. The basic principle is to use an integral circuit to convert the PWM wave into a smooth DC voltage, and then continuously adjust the PWM duty cycle by comparing it with the voltage to be measured until the output of the comparator changes from 0 to 1, and record the current PWM duty cycle, thereby realizing the measurement of the analog voltage.