HDP24-24-16PN vs T 3261 055

| Part Number |

|

|

| Category | Circular Connectors - Housings | Circular Connectors - Housings |

| Manufacturer | TE Connectivity Deutsch Connectors | Amphenol Sine Systems Corp |

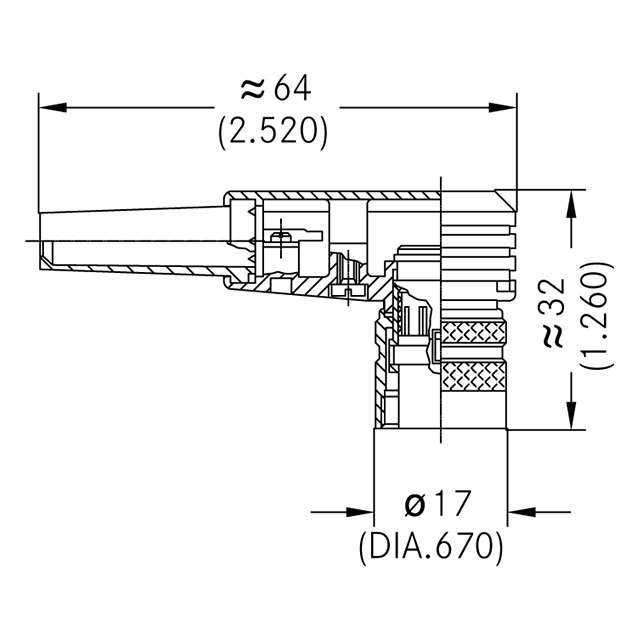

| Description | CONN RCPT HSG MALE 16POS PNL MNT | CONN PLG HSG FMALE 3PS INLINE RA |

| Package | - | - |

| Series | HDP20 | C 091 A |

| Type | For Male Pins | For Female Sockets |

| Features | Dust Cap | Cable Clamp, Coupling Nut, Strain Relief |

| Mounting Type | Panel Mount | Free Hanging (In-Line), Right Angle |

| Ingress Protection | IP67 - Dust Tight, Waterproof | IP40 |

| Orientation | Keyed | Keyed |

| Number of Positions | 16 | 3 |

| Mounting Feature | Bulkhead - Front Side Nut | - |

| Connector Type | Receptacle Housing | Plug Housing |

| Shielding | Unshielded | Shielded |

| Contact Type | Crimp | Crimp |

| Shell Size - Insert | 24-16 | DIN (180 Degree) |

| Fastening Type | Bayonet Lock | Threaded |

| Contact Size | 12 | 1.5mm |

| Shell Material | Polyamide (PA66), Nylon 6/6, Glass Filled | Die Cast |

| Housing Color | Black | Silver |

| Material Flammability Rating | UL94 V-1 | UL94 V-0 |

| Shell Finish | - | Nickel |

-

1. What is a circular connector housing?

A circular connector housing is a structural component used to protect internal connectors and cables, typically providing mechanical support and environmental sealing to prevent dust, water, chemicals, or physical damage.

-

2. What is the protection level of the circular connector housing?

The protection level is usually represented by an IP code, such as IP67. This level indicates the protective ability of the shell against solids (such as dust) and liquids (such as water). High IP rating is suitable for outdoor and harsh environments.

-

3. Does the circular connector housing have shielding function?

Some metal casings provide electromagnetic shielding (EMI/RFI) for high-frequency signal transmission applications to prevent electromagnetic interference.

-

4. How can circular connector housings improve the durability of connectors?

The shell can significantly extend the service life of the connector in harsh environments by providing protective measures such as mechanical strength, dust prevention, and waterproofing.