LMP90078MH/NOPB vs LMP90078MHX/NOPB

| Part Number |

|

|

| Category | Data Acquisition - Analog Front End (AFE) | Data Acquisition - Analog Front End (AFE) |

| Manufacturer | National Semiconductor | Texas Instruments |

| Description | LMP90078 MULTI-CHANNEL, LOW-POWE | IC AFE 1 CHAN 16BIT 28HTSSOP |

| Package | Bulk | Cut Tape (CT) |

| Series | - | - |

| Mounting Type | Surface Mount | Surface Mount |

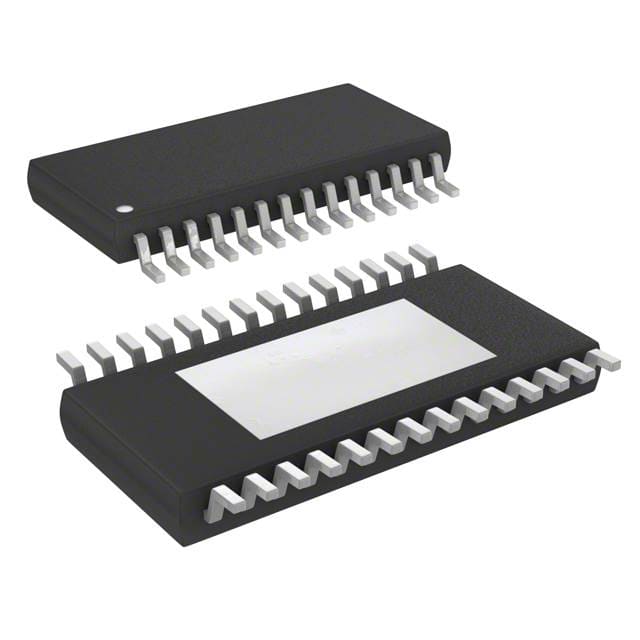

| Package / Case | 28-TSSOP (0.173\", 4.40mm Width) | 28-TSSOP (0.173\", 4.40mm Width) Exposed Pad |

| Supplier Device Package | 28-TSSOP | 28-HTSSOP |

| Power (Watts) | - | - |

| Number of Channels | 1 | 1 |

| Number of Bits | 16 | 16 |

| Voltage - Supply, Analog | 2.85V ~ 5.5V | 2.85V ~ 5.5V |

| Voltage - Supply, Digital | 2.7V ~ 5.5V | 2.7V ~ 5.5V |

-

1. What is analog data acquisition?

Analog data acquisition refers to the process of converting continuously changing signals of physical quantities into digital signals so that computers can process and record these signals. An analog data collector is a hardware device that can convert analog signals of physical quantities into digital signals and transmit them to a computer for processing and recording.

Basic principles of analog data acquisition

The process of analog data acquisition includes the following steps:

Sensor or circuit amplifier processing: The analog signal is first processed by a sensor or circuit amplifier.

Analog quantity collector collection: The processed analog signal is collected by the analog quantity collector and converted into a digital signal.

Transmission to computer processing: The converted digital signal is transmitted to the computer for processing and recording.

What is an analog front end?

Analog Front End (AFE) refers to a key module located between the sensor or signal source and the digital processing part in an electronic system. It is mainly responsible for processing and conditioning the analog signal from the sensor to make it suitable for subsequent digital processing and analysis. The analog front end usually includes functional modules such as amplification, filtering, multiplexing and analog-to-digital conversion (ADC). Its core function is to convert analog signals into digital signals for further processing and analysis.

Definition and Principle

The analog front end provides a simulation test platform for the back-end system or algorithm by simulating various input signals, environmental conditions and interactive processes for performance evaluation, functional verification, debugging and optimization. It converts real-world situations into data and situations that can be tested and analyzed by simulating specific input signals, environmental conditions and operating processes, providing an accurate simulation environment for subsequent processing. -

2. What is ADC in data acquisition system?

ADC (Analog-to-Digital Converter) is an electronic device that converts analog signals into digital signals. Its main function is to convert continuously changing analog signals (such as voltage, current, etc.) into discrete digital signals for processing and analysis by digital systems (such as microcontrollers, DSPs, etc.).

Working Principle of ADC

The working principle of ADC includes the following core steps:

Sampling: Read the input analog signal at a fixed time interval to obtain the instantaneous voltage value. The sampling frequency is determined by the sampling rate of the ADC.

Hold: Temporarily fix the instantaneous voltage value obtained by sampling inside the ADC for subsequent processing to prevent the input signal from changing during the quantization process.

Quantization: Map the sampled analog voltage value to a finite discrete digital level, and convert the continuous analog value into a discrete digital value.

Encoding Encode the quantized digital signal and output it as a digital signal. -

3. What is the analog front end in BMS?

The analog front end (AFE) chip in BMS is a key component in the battery management system (BMS). It is mainly responsible for collecting battery parameters such as voltage, current and temperature, and performing corresponding processing and protection.

The specific functions of the AFE chip include:

Voltage, current and temperature measurement: The AFE chip monitors the battery voltage, current and temperature in real time through high-precision analog-to-digital conversion and filtering processing to ensure the safety and life of the battery.

Signal acquisition: Collect analog signals such as voltage and current from the battery, and convert and process them.

Communication: Exchange information with external devices such as controllers to solve problems such as safety, availability, and ease of use in lithium battery systems.

Protection function: Provide battery voltage, temperature and current readings through a high-precision fuel gauge to prevent battery overcharge, over discharge and short circuit. -

4. What is the difference between ADC and AFE?

The main difference between ADC (analog-to-digital converter) and AFE (analog front end) lies in their functions and application scenarios.

The main function of ADC is to convert analog signals into digital signals, while AFE is a more complex integrated component that includes sensor interface, analog signal conditioning circuit, multi-way switch, sample and hold, ADC, data cache and control logic. AFE not only performs the functions of ADC, but also contains additional signal conditioning functions such as filtering, amplification and digital signal processing, which makes it more efficient and flexible in processing complex signals.