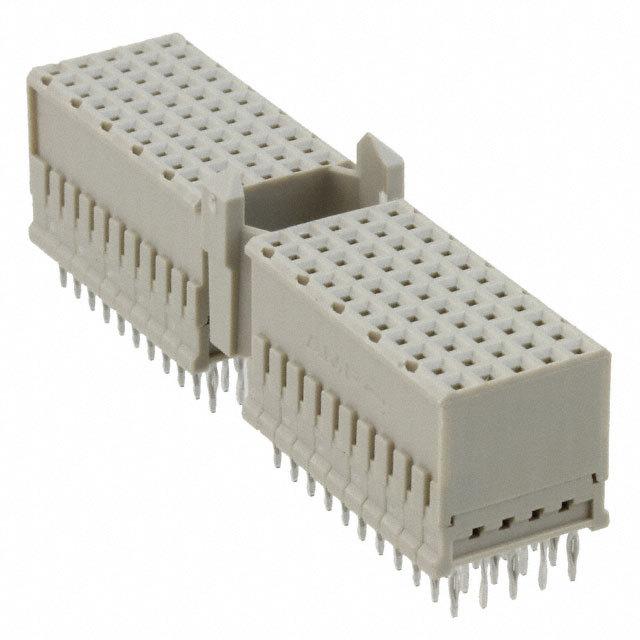

UHM-S110A3-5AP1-TG30 vs 5352457-1

| Part Number |

|

|

| Category | Backplane Connectors - Hard Metric, Standard | Backplane Connectors - Hard Metric, Standard |

| Manufacturer | 3M | TE Connectivity AMP Connectors |

| Description | CONN SOCKET 110POS UHM TYPE A | CONN RECEPT 110POS TYPE A VERT |

| Package | - | - |

| Series | UHM | Z-PACK |

| Mounting Type | Through Hole, Right Angle | Through Hole |

| Termination | Press-Fit | Press-Fit |

| Contact Finish | Gold | Gold |

| Number of Positions | 110 | 110 |

| Pitch | 0.079" (2.00mm) | 0.079" (2.00mm) |

| Connector Type | Receptacle, Female Sockets | Receptacle, Female Sockets |

| Contact Finish Thickness | 30µin (0.76µm) | 30µin (0.76µm) |

| Number of Positions Loaded | All | All |

| Number of Rows | 5 | 5 |

| Connector Style | A 22 | A 22 |

| Connector Usage | CompactPCI | Backplane |

-

1. What is a backplane connector?

A backplane connector is an electronic device component used to connect the motherboard and the daughterboard. It is mainly used to realize signal interconnection and power supply between various types of daughter cards in the system. Backplane connectors are usually installed on the backplane PCB, and have the advantages of high contact density, fast signal transmission rate, ensuring signal transmission accuracy, long service life and convenient installation.

Types and application scenarios

Backplane connectors can be divided into high-speed backplane connectors, medium-speed backplane connectors and low-speed backplane connectors according to the transmission speed. High-speed backplane connectors are mainstream products in the market and are widely used in 5G communication base stations, data centers and other scenarios, which can effectively improve the signal transmission rate.

Structure and working principle

Backplane connectors are usually composed of multiple components, including contact interfaces, contact coatings, contact elastic components and connector plastic bodies. These components work together to realize the connection and separation between wires, cables, printed circuit boards and electronic components, transmit signals and exchange information.

Market status and development trends

The main manufacturers in the global backplane connector market include Samtec, Amphenol, TE, etc. The localization process of the Chinese market is also accelerating, and many companies have begun to lay out the research and development and production of backplane connectors, such as Huafeng Technology. With the improvement of 5G network coverage, the demand for backplane connectors will further increase, and the market prospects are broad. -

2. What is the purpose of the backplane connector?

The main purpose of the backplane connector is to connect the motherboard and the daughterboard to achieve high-speed signal transmission and power supply. Backplane connectors usually have the advantages of high contact density, fast signal transmission rate, ensuring signal transmission accuracy, long service life, and convenient installation. They are widely used in communication systems, consumer electronics, aerospace, military industry, and industrial control.

-

3. What is a power backplane?

The power backplane is a metal plate installed at the rear of the server chassis. It integrates complex circuits and is mainly responsible for converting external input power into the DC power required by various components inside the server, and efficiently and safely distributes it to key components such as CPU, memory, hard disk, and graphics card. The power backplane achieves stable current output and overload protection through precise circuit design, ensuring the stability and reliability of the server under high-load operation.

Core functions and design principles of power backplane

Voltage conversion: The power backplane converts external input power into the DC power required by various components inside the server.

Current stable output and overload protection: Through precise circuit design, stable current output is achieved, and overload protection is performed when necessary to ensure the stable operation of the server.

Intelligent management: The power backplane is also embedded with intelligent monitoring and management functions, such as current monitoring, temperature sensing, fault warning, etc., so that operation and maintenance personnel can monitor the power status of the server in real time and respond to potential problems in a timely manner. -

4. What are the two types of connectors?

There are two main types of connectors: contact connectors and non-contact connectors. Contact connectors transmit signals or electrical energy through physical contact, and common ones include optical fiber connectors and electrical connectors; contactless connectors transmit signals through electromagnetic induction and other methods, such as proximity switches.

Contact connectors

Contact connectors transmit signals or electrical energy through physical contact, and mainly include the following types:

Fiber optic connectors: used for optical fiber connections in optical fiber communication systems, with advantages such as low loss, high transmission capacity and anti-electromagnetic interference, and are widely used in communication networks, data centers and other fields.

Electrical connectors: including plugs, sockets, etc., used to transmit low-voltage and low-current signals or high-voltage and high-current power signals, and are widely used in electronic equipment, communication networks, power systems, etc.

Contactless connectors

Contactless connectors transmit signals through electromagnetic induction and other methods, and common ones include proximity switches. Proximity switches can detect the proximity of objects without physical contact and are often used in automation equipment and sensors.