SMT knowledge introduction, PCBA, IC, semiconductor, SMT

SMT knowledge introduction, PCBA, IC, semiconductor, SMT

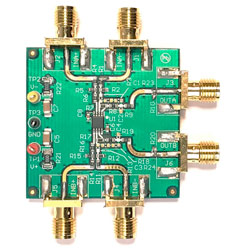

High assembly density, small size and light weight of electronic products. The volume and weight of SMD components are only about 1/10 of traditional plug-in components. Generally, after SMT is adopted, the volume of electronic products is reduced by 40%~60%, and the weight is reduced by 60%~ 80%. High reliability and strong anti-vibration ability. The defect rate of solder joints is low. Good high frequency characteristics. Reduce electromagnetic and radio frequency interference. It is easy to realize automation and improve production efficiency. Reduce costs by 30%~50%. Save materials, energy, equipment, manpower, time, etc. Electronic products are pursuing miniaturization, and the previously used perforated plug-in components can no longer be reduced. Electronic products have more complete functions. The integrated circuits (ICs) used no longer have perforated components, especially large-scale and highly integrated ICs, so surface mount components have to be used. Mass production of products and automation of production. The factory must produce high-quality products at low cost and high output to meet customer needs and strengthen market competitiveness. The development of electronic components, the development of integrated circuits (IC), and the multi-application of semiconductor materials. Electronic technology revolution. It is imperative that chasing the international trend also pollutes and destroys the air and atmosphere. The residue of cleaning agent on the board will cause corrosion, which will seriously affect the quality of the product. Reduce cleaning process operation and machine maintenance costs.

No-cleaning can reduce the damage caused by PCBA during moving and cleaning. There are still some components that cannot be cleaned. The flux residue has been controlled and can be used in accordance with the product appearance requirements to avoid the problem of visual inspection of the clean state. The residual flux has been continuously improved its electrical performance to avoid leakage of the finished product and cause any damage.

Bridging: Generally speaking, the cause of solder bridges is that the solder paste is too thin, including low metal or solid content in the solder paste, low thixotropy, easy squeezing of the solder paste, too large solder paste particles, and too small flux surface tension. . Too much solder paste on the pad, too high peak reflow temperature, etc.

Open: Reasons: 1. The amount of solder paste is not enough. 2. The coplanarity of component pins is not enough. 3. The tin is not wet enough (not enough to melt, and the fluidity is not good), and the tin paste is too thin to cause tin loss. 4. The pin sucks tin (like rush grass) or there is a connection hole nearby. The coplanarity of the pins is particularly important for fine-pitch and ultra-fine-pitch pin components. One solution is to apply tin on the pads in advance. The pin sucking can be prevented by slowing down the heating speed and heating the bottom surface more and less heating on the top surface. It is also possible to use a flux with a slower wetting speed and a high active temperature or a solder paste with different ratios of Sn/Pb to retard the melting to reduce the pin sucking tin. ◆ SMT-related technology composition design and manufacturing technology of electronic components and integrated circuits. Circuit design technology of electronic products. Circuit board manufacturing technology. Design and manufacturing technology of automatic placement equipment. Circuit assembly manufacturing technology. Development and production technology of auxiliary materials used in assembly and manufacturing. ◆ Mounter: Arch type (Gantry): The component feeder and the substrate (PCB) are fixed, and the placement head (with multiple vacuum suction nozzles installed) moves back and forth between the feeder and the substrate to move the component from the feeder Take it out, adjust the position and direction of the component, and then place it on the substrate. Since the placement head is installed on the arch-type X/Y coordinate moving beam, it is named after.

The method of adjusting the position and direction of the component: 1). Mechanical centering, adjusting the position, and adjusting the direction of the nozzle rotation. The accuracy that this method can achieve is limited, and the later models are no longer used. 2) Laser recognition, X/Y coordinate system adjustment position, nozzle rotation adjustment direction, this method can realize the recognition during the flight, but it cannot be used for the ball grid array element bga. 3) Camera recognition, X/Y coordinate system adjustment position, nozzle rotation adjustment direction, generally the camera is fixed, the placement head flies over the camera to perform imaging recognition, which takes a little longer than laser recognition, but it can recognize any component, and there are The camera recognition system that realizes recognition during flight has other sacrifices in terms of mechanical structure. In this form, the speed of the placement head is limited due to the long back and forth movement. At present, multiple vacuum suction nozzles are generally used to take materials at the same time (up to ten) and a double beam system is used to increase the speed, that is, the placement head on one beam is taking the material while the placement head on the other beam is placed Components, the speed is almost twice as fast as the single beam system. However, in practical applications, it is difficult to achieve the conditions of simultaneous reclaiming, and different types of components need to be replaced with different vacuum suction nozzles, and there is a time delay in changing the suction nozzles. The advantages of this type of model are: the system has a simple structure, can achieve high precision, and is suitable for components of various sizes and shapes, and even special-shaped components. The feeder has the form of belt, tube, and tray. It is suitable for small and medium batch production, and can also be used for mass production by combining multiple machines.

Turret type (Turret): The component feeder is placed on a single-coordinate moving cart, the substrate (PCB) is placed on a worktable moved by the X/Y coordinate system, and the placement head is installed on a turret. , The feeder moves the component feeder to the reclaiming position, the vacuum suction nozzle on the placement head takes the components at the reclaiming position, and rotates to the placement position (180 degrees from the reclaiming position) through the turret. During the rotation After adjusting the position and direction of the component, the component is placed on the substrate.

The method of adjusting the position and direction of the component: 1). Mechanical centering, adjusting the position, and adjusting the direction of the nozzle rotation. The accuracy that this method can achieve is limited, and the later models are no longer used. 2) Camera recognition, X/Y coordinate system adjustment position, nozzle self-rotation adjustment direction, the camera is fixed, the placement head flies over the camera to perform imaging recognition. Generally, there are more than ten to twenty placement heads installed on the turret, and each placement head is equipped with 2~4 vacuum nozzles (earlier models) to 5-6 vacuum nozzles (current models). Due to the characteristics of the turret, the actions are miniaturized, and the actions such as changing the nozzle, moving the feeder in place, taking components, component recognition, angle adjustment, table movement (including position adjustment), and placing components can all be done in the same time period. It is completed within, so real high speed is achieved. At present, the fastest time period is 0.08~0.10 seconds for a piece of component.

This model is superior in speed and is suitable for mass production, but it can only use tape-packaged components. If it is a dense-footed, large-scale integrated circuit (IC), it cannot be completed with only tray packaging. Rely on other models to work together. .