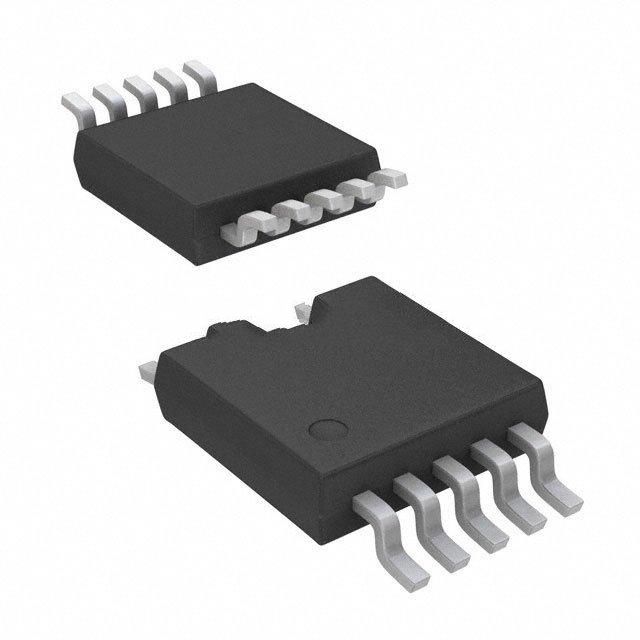

ADC104S021CIMMX/NOPB vs ADS1015BQDGSRQ1

| Part Number |

|

|

| Category | Data Acquisition - Analog to Digital Converters (ADC) | Data Acquisition - Analog to Digital Converters (ADC) |

| Manufacturer | Texas Instruments | Texas Instruments |

| Description | IC ADC 10BIT SAR 10VSSOP | IC ADC 12BIT SIGMA-DELTA 10VSSOP |

| Package | Cut Tape (CT) | Cut Tape (CT) |

| Series | Automotive, AEC-Q100 | Automotive, AEC-Q100 |

| Features | - | PGA |

| Operating Temperature | -40°C ~ 85°C | -40°C ~ 124°C |

| Mounting Type | Surface Mount | Surface Mount |

| Package / Case | 10-TFSOP, 10-MSOP (0.118\", 3.00mm Width) | 10-TFSOP, 10-MSOP (0.118\", 3.00mm Width) |

| Supplier Device Package | 10-VSSOP | 10-VSSOP |

| Reference Type | Supply | Internal |

| Sampling Rate (Per Second) | 200k | 3.3k |

| Data Interface | SPI, DSP | I²C |

| Number of Bits | 10 | 12 |

| Voltage - Supply, Analog | 2.7V ~ 5.25V | 2V ~ 5.5V |

| Voltage - Supply, Digital | 2.7V ~ 5.25V | 2V ~ 5.5V |

| Number of Inputs | 4 | 2, 4 |

| Input Type | Single Ended | Differential, Single Ended |

| Configuration | MUX-S/H-ADC | MUX-PGA-ADC |

| Ratio - S/H:ADC | 1:1 | 0:1 |

| Number of A/D Converters | 1 | 1 |

| Architecture | SAR | Sigma-Delta |

-

1. What is ADC for data acquisition?

A data collector is an electronic device used to convert various data (such as barcodes, RFID tags, etc.) into a storable and editable format and transmit it to a computer or system in real time. Data collectors are usually operated using handheld devices (such as inventory counting machines or PDAs) and have functions such as real-time acquisition, automatic storage, instant display, instant feedback, automatic processing, and automatic transmission. They can be widely used in warehouse management, logistics transportation, retail, medical, military and other fields. The main functions of data collectors include data acquisition, real-time data processing, data storage and transmission.

ADC, or analog-to-digital converter, is an electronic device that can convert continuously changing analog signals into discrete digital signals. It is mainly used in data acquisition, signal processing, communication and other fields.

-

2. How does ADC convert analog to digital?

The technology that converts analog sound signals into digital signals is called analog-to-digital conversion technology (Analog to Digital Converter, referred to as ADC). The function of ADC is to convert continuously changing analog signals into discrete digital signals. The process of analog-to-digital conversion can be completed by steps such as sampling, holding, quantization, and encoding.

-

3. What is the main purpose of ADC?

The main purpose of ADC is to convert the input analog signal into a digital signal.

ADC, or analog-to-digital converter, is mainly used to convert continuously changing analog signals into discrete digital signals. The implementation process of ADC usually includes four steps: sampling, holding, quantization, and encoding.

-

4. What process converts analog to digital?

There are three basic processes for analog to digital conversion:

The first process is "sampling", which is to extract the sample value of the analog signal at equal intervals to turn the continuous signal into a discrete signal.

The second process is called "quantization", which is to convert the extracted sample value into the closest digital value to represent the size of the extracted sample value.

The third process is "encoding", which is to represent the quantized value with a set of binary digits. After these three processes, the digitization of the analog signal can be completed. This method is called "pulse encoding".

After the digital signal is transmitted to the receiving end, a restoration process is required, that is, the received digital signal is converted back to an analog signal so that it can be understood by the receiver. This process is called "digital-to-analog conversion", which reproduces it as sound or image.