The Eight Most Popular Motor Driver Development Boards(TI ,ST, Microchip,onsemi,ADI,Infineon)

The Eight Most Popular Motor Driver Development Boards

As a device that converts electrical energy into mechanical energy, motors are rich in variety and widely used, and can be seen everywhere in industries, automobiles, agriculture, offices, home appliances and other scenarios. Taking the motor used in the electronic control system of new energy vehicles as an example, it will involve four categories: DC motor, AC asynchronous motor, permanent magnet synchronous motor and switched reluctance motor.

It has been nearly 200 years since the British physicist and chemist Faraday invented the first motor in the true sense in 1831. The focus of the motor industry has also shifted from DC brush motors and AC asynchronous motors to permanent magnet synchronous motors and DC brushless motors. With many advantages such as high efficiency, high power factor, high reliability, low temperature rise, and small size, permanent magnet synchronous motors have been widely used in many fields, including aerospace, petroleum metallurgy, industry and agriculture, and medical equipment. Brush motors have outstanding advantages such as high efficiency, long life, simple structure, reliable operation, and convenient maintenance. They have formed large-scale applications in the fields of household appliances, office equipment, industrial equipment and medical equipment, and have great market potential waiting for everyone to deepen. dig.

The advancement of technology promotes the rapid development of the market. According to the statistics of Grand View Research, a market research organization, the sales scale of the global motor market in 2020 has reached 150.5 billion US dollars. From 2020 to 2027, the global motor market sales scale is expected to increase by 6.4%. The compound annual growth rate continues to climb, reaching $232.5 billion by 2027.

For motor applications, in addition to the need to select a suitable motor type, the drive control circuit is also very important. Generally, it consists of a main processor, an incremental encoder and a driver chip. It is the key to improving the energy efficiency of the motor. The advanced technology and products The degree is directly linked to the level of energy conservation and emission reduction. Therefore, if a suitable motor driver chip can be found, it can help the design of motor solutions in terms of development efficiency, system energy efficiency, integration and reliability.

——A large inventory of eight mainstream motor drive chips. These innovative motor drive solutions from well-known manufacturers are not only rich in types, but also have their own advantages. They are the best choice for designing motor-related applications.

ToshibaTB9058FNG Motor Driver

The TB9058FNG is an AEC-Q100 qualified automotive DC servo motor driver capable of measuring the current motor position, controlling the motor rotation, and ensuring the rotation to the target position.

The driver is based on the Local Internet Network (LIN) 1.3 protocol specification, capable of data communication with the LIN bus at a communication rate of 19200bps / 9600bps / 4800bps / 2400bps, and can connect up to 16 devices as slave devices on a single bus.

The TB9058FNG operates from a power supply voltage range of 7V to 18V, and consumes ≤10µA of standby current. Before the device wakes up, it is expected to wait at least 10ms to start receiving data, considering the time required for oscillation stabilization.

The driver has excellent protection features, including enhanced calibration function, ±1.5A driver short-circuit protection, and over-temperature and over-voltage protection circuits.

The MC33HB2000AES is a SMARTMOS monolithic half-bridge IC, an H-bridge motor driver designed using the ISO 26262 process, compliant with AEC-Q100 Grade 1, and able to meet the stringent requirements of automotive applications, including electronic throttle control, exhaust gas recirculation (EGR) Controls, Turbine, Vortex and Rotary and Waste Baffle Controls, Electric Pumps, Motor Controls and Accessories.

The MC33HB2000AES has an operating voltage range of 5V to 28V, and can control inductive loads with peak currents greater than 10A. The nominal continuous average load current is 3A. The current mirror output signal with an error of less than 5% provides high-precision real-time current feedback.

This is the functional block diagram of this power supply IC. This driver provides a means to efficiently drive forward and reverse shaft rotation of a DC motor through a monolithic H-bridge consisting of a low RDS(on) N-channel MOSFET and integrated control circuitry. The switching action of the H-bridge can be pulse width modulated for torque and speed control in eight steps from 0.25V/μs to 16V/μs, giving users the flexibility to meet EMI requirements and minimize switching losses. The outputs consist of four power MOSFETs configured as a standard H-bridge, controlled by the IN1 and IN2 inputs.

MC33HB2000AES Features

The MC33HB2000AES provides several safety and protection features including charge pump undervoltage, overvoltage and VPWR undervoltage, short to ground and short to VPWR (per output), open load, temperature warning and thermal shutdown. At the same time, the power IC is very scalable, and the SPI programmable current limit and slew rate allow the use of the same motor driver for various motor sizes.

ADI Motor Driver MAX22203

The MAX22203 is a 65V, 3.8A dual-channel brushed or single-channel stepper motor driver that can be used to drive two brushed DC motors or a single stepper motor. There are two H-bridges inside the device, and the maximum operating voltage is 65V. Each H-bridge is individually controllable and features an extremely low typical RON (high side + low side) of 0.3Ω for high drive efficiency and reduced heat generation.

ADI-MAX22203

A highlight of the device is that the bridge output current is sensed by non-dissipative current sense circuits (ICs), which in contrast to configurable threshold currents (ITRIP) do not require external power resistors normally required. The ITRIP thresholds can be independently set for both full bridges by connecting external resistors to the REFA and REFB pins.

Numerous protection features are another highlight of the MAX22203, including overcurrent protection (OCP), thermal shutdown (TSD), and undervoltage lockout (UVLO). The open-drain active-low nFAULT pin is activated whenever a fault condition is detected. During thermal shutdown and undervoltage lockout, the driver is tri-stated until normal operation resumes.

In addition, the MAX22203 integrates current drive regulation (CDR), and the current sense external controller can use the CDR pin for various reasons, as shown in Figure 7 below when the motor rotates forward and DIN2 is held high (case A) or DIN2 Specific behavior of the CDR function when switching (cases B and C). For example, the pin duty cycle can be used to detect stall conditions.

CDR Behavior of ADI MAX22203

The MAX22203 can be used in brushed DC motor drivers, stepper motor drivers, solenoid drivers, latching valves

Infineon IM818-LCC Intelligent Power Module

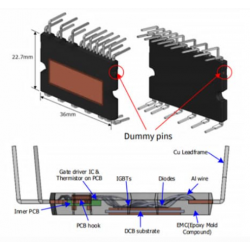

IM818LCCXKMA1 is a fully isolated dual-in-line CIPOS Maxi 1200V, 15A three-phase smart power module in DIP 36x23D package, providing a full-featured compact inverter solution for motor drive applications, which can be used to control variable speed drive applications of three-phase AC motors and permanent magnet motors, including industrial drives, fans and pumps, HVAC outdoor fans, active filters, and more.

Infineon IM818LCCXKMA1

Infineon

The IM818LCCXKMA1 is based on 1200V TRENCHSTOP IGBT technology, which significantly improves the static and dynamic performance of the device. At the same time, this IGBT technology, together with the soft-recovery emitter-controlled diode inside the device, reduces conduction losses, which significantly improves system efficiency.

The CIPOS Maxi IPM design makes the IM818LCCXKMA1 a high-performance and cost-effective choice, integrating various power and control components to improve reliability, optimize PCB size and system cost. IM818LCCXKMA1 is undoubtedly an ideal choice when the design scheme of an engineer friend pays special attention to power density. The CIPOS Maxi IPM design realizes the ultra-small package of 1200V IPM level, which can improve the power density in modules and systems, and has no difference in size and performance. compromise.

The IM818LCCXKMA1 provides excellent protection capabilities, including overcurrent shutdown, phase current monitoring, temperature monitoring, and undervoltage lockout functions. Combined with the excellent thermal performance of the DCB substrate, it is especially suitable for applications requiring good thermal performance and electrical isolation, strong EMI. control capability as well as overload protection for power applications. Here we focus on interpreting the overcurrent shutdown and undervoltage lockout functions.

IM818LCCXKMA1 has SCSOA (Short-Circuit Safe Operating Area) performance, as shown in Figure 9, if the short-circuit time is less than 16.0μs, the IGBT has the ability to turn off safely. In this case, the IGBT can be turned off with a peak SC current of about 46.8A (non-repetitive) at a control supply voltage of 17.5V.

The IM818LCCXKMA1 provides robust 1200V SOI gate driver technology through a buried silicon oxide layer and can prevent leakage or latch-up current between adjacent devices, preventing latch-up for improved robustness. This protection technology for 6 switches is capable of shutting down all 6 switches under fault conditions such as undervoltage lockout or overvoltage.

, IM818LCCXKMA1 integrates IGBT, diode, gate driver IC and thermistor, and is suitable for space-constrained industrial applications through an ultra-compact footprint.

ON Semiconductor NCD57084 Isolated IGBT Gate Driver

The NCD57084 is a high current single channel IGBT gate driver with 2.5kVrms internal galvanic isolation designed for high system efficiency and reliability in high power applications. The driver includes current sensing with soft shutdown and fault reporting in a narrow body SOIC8 package.

onsemi-NCD57084

NCD57084 features low output impedance for enhanced IGBT drive, provides wide input bias voltage range and signal level from 3.3V to 20.0V, and wide output bias voltage range up to 30.0V, supports +7A/-7A high peak output current. It can be seen from Figure 12 that the device has a short propagation delay and can achieve precise matching. The small UVLO threshold enables bias flexibility.

onsemi: NCD57084 propagation delay, rise and fall times

Designed for high system efficiency and reliability in high power applications, the NCD57084 features several protection mechanisms including IGBT gate clamping during short circuit, soft shutdown during IGBT overcurrent, 2.5kVrms galvanic isolation, high transient immunity It can be used in motor control, uninterruptible power supply (UPS), industrial power supply, HVAC, industrial pumps and fans, etc.

Microchip PIC32CM MC00 Motor Control MCU

The PIC32CM1216MC00048-I/U5B is a motor control microcontroller (MCU) based on the Arm Cortex-M0+ core, running at up to 48MHz, featuring a single-cycle hardware multiplier and MPU, providing 128KB Flash, 16KB SRAM main memory, and 4KB Flash (for data flash).

Microchip: PIC32CM1216MC00048-I/U5B

An overview of the power domain of this MCU, providing functions such as 48MHz to 96MHz Fractional Digital Phase Locked Loop (FDPLL), Power-On Reset (POR), and Brown-Out Detect (BOD). In addition, it includes a 16-bit sigma-delta analog-to-digital converter (SDADC), two 12-bit 1Msps analog-to-digital converters (ADC), a 10-bit 350ksps digital-to-analog converter (DAC), and two analog comparators ( AC) and other advanced modules.

Microchip: PIC32CM1216MC00048-I/U5B Power Domain Overview

In terms of motor control, the MCU provides two 24-bit timer/counters and one 16-bit timer/counter (TCC), with extended functions including:

Up to 4 compare channels with optional complementary outputs;

Generate synchronous pulse width modulation (PWM) patterns on port pins;

Deterministic fault protection, fast decay and configurable dead time between complementary outputs;

Can increase resolution (up to 5 bits) and reduce jitter for quantization errors;

Up to 8 waveform output channels.

TI three-phase gate driver DRV8300NIPWR

The DRV8300NIPWR is a 100V three-phase half-bridge gate driver, each half-bridge gate driver can drive high-side and low-side N-channel power MOSFETs, using integrated bootstrap diodes and external capacitors to generate the correct gate drive for the high-side MOSFET Voltage. Applications include e-bikes, e-scooters and e-mobility, fans, pumps and servo drives, brushless DC (BLDC) motor modules and PMSMs, cordless vacuum cleaners, as well as drones, robots and RC toys.

TI: DRV8300NIPWR

In the DRV8300NIPWR simplified schematic, GVDD is used to generate the gate drive voltage for the low-side MOSFET. The gate drive architecture supports source currents up to 750mA peak and sink currents up to 1.5A; supports inverting and non-inverting INLx inputs; phase pin SHx can Withstands negative transients up to -22V; BSTx and GHx can support higher absolute maximum voltages for positive voltage transients (115V), improving system robustness; undervoltage lockout for low-side and high-side via GVDD and BST Provides undervoltage protection; via D

Adjustable dead time on T pin for QFN package variants.

TI: DRV8300NIPWR Simplified Schematic

In addition, the DRV8300NIPWR's small propagation delay and delay matching performance greatly reduces dead-time requirements, further improving efficiency.

ST motor controller STSPIN32G4

STSPIN32G4 is a motor controller with STM32G4 MCU to drive three-phase brushless motors. The device features a highly integrated, flexible product with embedded three half-bridge gate drivers with 1A current capability (source and sink); embedded three bootstrap diodes; embedded programmable buck regulator with embedded It can generate the power supply voltage for the gate driver from the motor supply voltage VM; it comes with an integrated MCU (STM32G431VBx3), the operating frequency is up to 170MHz; the MCU also integrates high-speed memory (128kB flash memory and 32kB SRAM), and has multiple protection mechanisms and up to 40 pins of GPIO available.

ST: STSPIN32G4

As a result, the device can significantly reduce PCB area and overall bill of materials. Thanks to the embedded flexible power management features, the device is self-powered and can generate all the required power from the motor supply voltage VM, which is the only power supplied externally.

The built-in STM32G4 MCU is a highlight of the motor controller, which significantly reduces the development difficulty of motor applications and gives the solution intelligent capabilities. This MCU has rich, specific features, making it a mainstream choice for advanced motor control applications. At the same time, the processor features a single-precision floating-point unit (FPU), a full set of DSP (digital signal processing) instructions and a memory protection unit (MPU) to support motor control algorithms that run very well, even in challenging motion control It also provides excellent flexibility in the selection of suitable controls for the application.

In terms of protection functions, the STSPIN32G4 benefits from the integrated interlock function, which cannot drive the high-side and low-side switches of the same half-bridge at the same time. Another protection feature is a hardware VDS monitoring circuit that continuously monitors each of the six external MOSFETs. When overvoltage is detected on one of them, it shuts down all gate driver outputs. The overvoltage threshold is set through a dedicated SCREF pin.

Excellent performance allows STSPIN32G4 to be widely used in industrial and home automation, servo drives and electric bicycles, service and automation robots, pumps and fans, as well as drones and model aircraft and other rich scenarios.

If engineers and friends are interested in this device, they can also learn more about it through the EVSPIN32G4 demo board provided by ST. The manufacturer number on Mouser Electronics is EVSPIN32G4.

The demo board includes the STSPIN32G4 system and the STL110N10F7 power MOSFET. Thanks to the integrated voltage regulator, the gate driver and control logic power supply can be generated from the motor power supply, no dedicated circuit is required, and the STSPIN32G4 MCU can be easily and comprehensively understood.

Abundant interface resources are a major advantage of the EVSPIN32G4 demo board, with up to 40 GPIOs. At the same time, in order to better adapt the algorithm, the board can be configured as a three-shunt or single-shunt structure, supporting sensorless and sensor-based control algorithms.

Summarize:

The above-mentioned eight motor drive chips can be said to have their own strengths. Whether it is for the consumer electronics field with rapid product iteration, the industrial field with extremely complex use conditions, or the automotive field with stricter product quality requirements, they can all find suitable products. solution to help quickly create a market-competitive motor drive solution.