Familiar with SIMO PMIC, wearable device power supply design becomes easier

Familiar with SIMO PMIC, wearable device power supply design becomes easier

Portable electronic devices, especially wearable devices, are becoming an integral part of our daily life, and these devices make things very convenient for us to study, work, exercise, travel, communicate and monitor. For example, in medical applications, wearable devices can be used to monitor heart rate, blood pressure, blood oxygen levels, calories burned during exercise, sleep tracking, and more.

To provide a better user experience, high performance, small size, and low power consumption are key metrics for these wearable devices. Meeting these metrics often requires some trade-offs in circuit design. For example, to meet specific power consumption goals, designers often have to increase the size of the device.

So, is there a way to effectively extend the life of the battery without increasing the size of these battery-powered devices? The answer is: yes!

SIMO PMIC: Opening a window for small-scale, high-efficiency applications

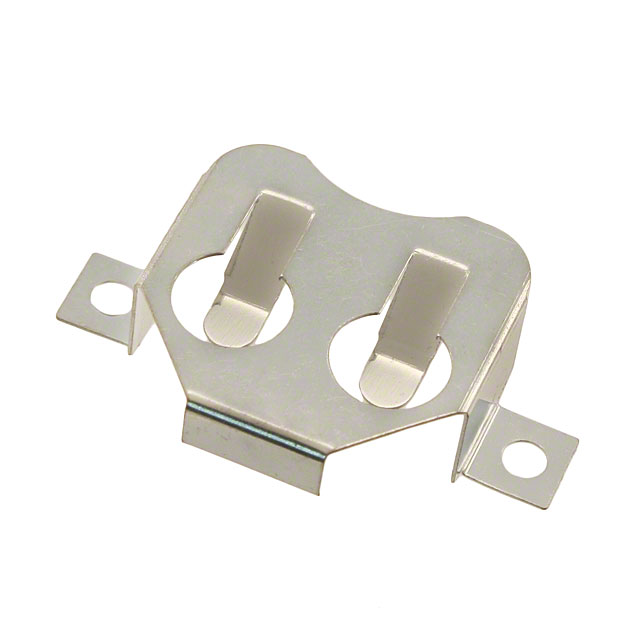

Wearable devices with a light and compact form factor often use tiny batteries. Although the capacity of batteries has increased over the past decade, the stored power is quickly depleted after a limited period of time. As a result, the cost of the wearable device increases by requiring regular replacement of the battery or replacing it with a rechargeable battery.

Power Management IC (PMIC) is a highly integrated power supply product that encapsulates a traditional multi-output power supply in a single chip, thereby achieving high efficiency in multiple power supply application scenarios with a smaller volume , commonly used in devices powered by batteries. When applied to wearable devices, the PMIC not only optimizes the layout, but also maximizes the energy efficiency of the system, effectively extending battery life.

Direct current to direct current (DC-DC) converters are the most commonly used PMICs in electronic products, and have become the main force in the market in recent years due to their high conversion efficiency. According to the different working modes and energy storage components, DC-DC converters can be divided into linear regulators (LDO), inductive buck/boost (Buck/Boost) switching DC-DC converters and capacitive switching DC-DC converters. DC converter (Switched Capacitor DC-DC Converter). The three different architectures of DC-DC converters have some differences in physical size, flexibility and efficiency, among which:

LDO can be fully integrated and has good voltage scalability, but the efficiency is not high;

Capacitive switching regulators can also be fully integrated and efficient, but have poor voltage scalability;

Inductive switching regulators are very efficient and voltage scalable, but have the disadvantage of not being fully integrated.

Capacitive switching regulators (also known as charge pumps) have extremely limited output voltage scalability. In general, charge pumps are considered a suitable choice for Gate Drivers. However, in the circuit of the wearable device, the current required by the charge pump to output a specific voltage is not equipped. Therefore, the wearable device mostly chooses the linear LDO and the inductive switching regulator (Buck/Boost), both of which can be used. Provides the flexible power management required in the design.

In the design of wearable devices, whether to choose a linear LDO or a buck/boost topology requires certain trade-offs. In the traditional switching regulator structure, each output of the regulator requires an independent inductor. These inductors are often bulky and expensive, which is not conducive to realizing small-sized packages. In order to reduce the size, people often choose compact and low noise LDO, but the loss of LDO is relatively large. Of course, there is no other way out, we have another option.

The PMIC based on the Single Inductor Multiple Output (SIMO) architecture uses a single inductor as an energy storage element to support multiple independent DC outputs. Compared with traditional DC-DC converters, SIMO power converters provide multiple outputs through a single inductor, integrating functions that would otherwise require multiple discrete components into a smaller package, saving space while still maintaining high efficiency. Small form factor devices with extended battery life provide the best solution.

Maxim SIMO PMIC Solution: Effectively Reduce Power Supply Size for IoT Devices

Continuously reducing the size of electronic products, reducing heat generation and improving efficiency, extending battery life, and enabling electronic products to provide more complete functions in consumers' lives are the consistent pursuit of system designers. Maxim Integrated (Maxim) has a wide range of SIMO PMIC products and solutions, with dedicated SIMO PMICs available for the unique design needs of portable equipment, such as the MAX77650 and MAX77651.

Both products are designed with a micropower SIMO step-up/step-down DC-DC converter with an integrated 150mA LDO to power noise-sensitive circuits. In the MAX77650/MAX77651, SIMO uses a single inductor to provide three independent programmable voltage outputs, creating an innovative power management solution ideal for small Li+ battery-powered products.

Based on the above solutions, Maxim has continued to expand its SIMO PMIC product portfolio, and subsequently launched a series of PMIC products such as MAX17270, MAX77278, MAX77640/MAX77641 and MAX77680/MAX77681, which reduced the size of the power management circuit by nearly half, and widely supported wearable Devices, hearables, sensors, automated control centers such as smart homes, and space-constrained products such as the Internet of Things (IoT).

TI Dual Power Converter TPS65135: Provides Power Driver for AMOLED Display

The TPS65135 device is a high-efficiency split-rail power supply from Texas Instruments (TI). The converter has a single inductor and multiple output (SIMO) topology, so very few external components are used. The device uses a buck/boost topology and generates positive and negative output voltages above or below the input supply voltage.

TI says that the TPS65135 has good line transient regulation, which is very necessary, for example, to avoid the interference of the input voltage deviation generated by the mobile communication system during the transmission phase on the mobile phone display. According to TI's application note, this feature is mainly derived from the SIMO topology, and the principle is as follows:

In discontinuous conduction mode (DCM), the current delivered to the output is determined by the peak and slope of the inductor current. As shown in Figure 3, the average output current shown in the shaded area is the same for different input voltages. Because the converter uses peak current mode control, the peak current is fixed as long as the load current is fixed. The falling slope of the inductor current is given by the difference between the positive and negative output voltages and the inductor value, independent of the input voltage.

Therefore, while discharging, any change in the input voltage will change the duty cycle of the converter, but not the peak or slope of the inductor current. Therefore, the average output current given by area A remains the same for any input voltage change

The TPS65135 product can be used to generate shunt rail power supplies from input supply voltages ranging from 2.5V to 5.5V and is optimized for the 3.3 V rail of single-cell Li-Ion batteries. Figure 4 shows a typical application of the TPS65135 in ±5V AMOLED display power supplies. . Operating in a buck-boost topology, the TPS65135 generates a positive and negative output voltage with only a 2.2µH inductor. When the output current mismatch reaches 50% or less, it can generate a positive output voltage as high as 6V and a negative voltage as low as -7V through a buck-boost (i.e. the input supply voltage may be higher or lower than the positive output voltage) . Both outputs are controlled by the EN pin: both outputs are enabled at a high logic level and disabled at a low logic level. The integrated UVLO function disables the device when the input supply voltage is too low for normal operation.

Epilogue

Thin, small, and light are physical requirements for wearable devices and the main reason why today's wearable technology limits battery life. Compliant conventional batteries, such as lithium-ion coin cells, may be suitable for sensors and other low-power wearables, but they struggle to meet the demands of more powerful wearables such as fitness bands and smartwatches. Extending battery life is critical for such devices to gain market acceptance. No one wants a smart wearable device's battery to run out in a few hours. However, the complex internal structure of the battery will greatly increase the size and cost of the device, making it inconvenient for people to wear.

In order to enable wearable devices to run for a long time, energy harvesting, battery management, power management and low power consumption solutions are all effective measures to prolong the battery life of wearable devices. The SIMO PMIC solution not only improves the energy efficiency of the device, but also greatly reduces the size of the circuit board due to its high level of integration. It is an ideal solution for the power management of battery-operated devices.