How to understand pre-purchased power device performance

How to understand pre-purchased power device performance

The development of human society is deeply bound to electrical energy, and electrical/electronic equipment is widely used in various fields such as industry, medical care, energy, transportation, and people's livelihood. As electrical equipment gradually evolves from a single circuit to a system, it is particularly important to distribute power reasonably and efficiently to each device in the system. An excellent power management system can not only ensure the safety of power consumption of the system, but also the key to high efficiency and energy saving of equipment.

As we all know, building a power management system is a complex project. Not only parameters such as input voltage, output voltage and current of a single device in the device should be considered, but also optimized design from the aspects of device energy efficiency, system parameters and heat dissipation. Be considerate too.

Innovation/Selection of Power Management Devices

In terms of product categories, power management devices are mainly divided into power management ICs and discrete power devices. The former includes multi-category and multi-model IC devices involved in output circuits, input circuits, feedback circuits, drive circuits and protection circuits; the latter is mainly the power semiconductor devices we often mention.

The power consumption of the system is the product of the energy consumption per unit time and the time. Therefore, reducing the power supply time of unnecessary devices and the power consumption of a single device/module are the two major points to solve the problem. In terms of power management device design, the main optimization points for improving energy efficiency are higher switching frequency, lower quiescent current, more advanced gate drivers and smaller passive components.

EMI is the second major concern, mainly system noise and interference. With the improvement of system integration and DC/DC switching speed, the importance of low EMI is self-evident, especially in the automotive and industrial fields. By integrating bypass capacitors and adopting high power supply rejection ratio regulators, the EMI generated by the system can be effectively reduced and the solution design can be simplified.

The development trend is integrated protection. In the process of system design, we can see various protection circuit designs. Today's advanced power management devices integrate various protection functions, such as undervoltage protection, overvoltage protection, current limit protection, short circuit protection, and thermal protection. The module power supply will adopt an isolated design, which can not only shield the interference of external equipment to maintain the integrity of the power supply signal, but also protect the power safety of the design and operator, and save the layout space.

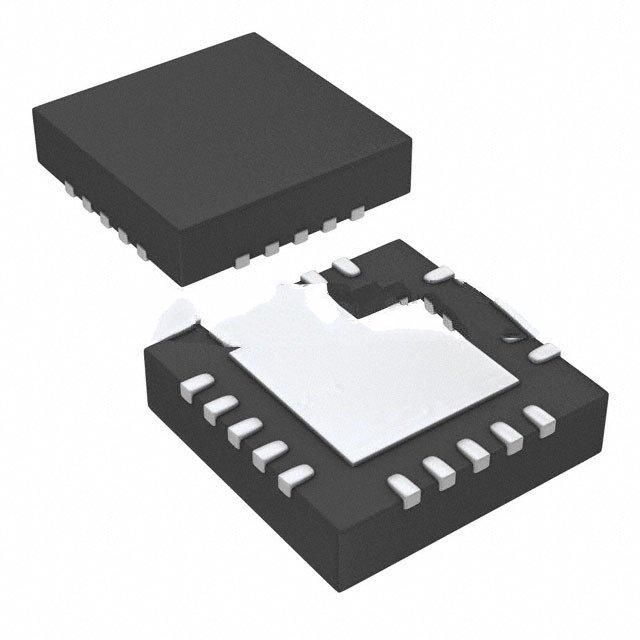

Under the innovation of high efficiency, low EMI, and high integrated protection, various types of power management devices are also focusing on improving the packaging design, in order to accommodate more innovative elements in a smaller and more reliable package, so as to allow the device itself and the use of The device scheme has higher power density. In this regard, heat dissipation from small packages is a major challenge, and manufacturers are also investing in developing packages with better thermal performance.

In some special fields, such as medical and electronic/power products, the common features such as low leakage current, less parasitic capacitance, high isolation voltage and low isolation capacitance must be paid attention to in the selection of power management devices, in order to surpass other industry EMC performance.

In addition to the consideration of product characteristic parameters, when building a complete power supply system, it is also necessary to comprehensively look at the topology circuit of the device, which is complementary to the innovation of electrical devices. Generally speaking, various types of power management devices will have their own mature topologies. Taking DC-DC converters as an example, Royer circuits are mostly used for constant voltage input, and Flyback and Forward topologies are used for wide input ranges. These mature topologies have stood the test of time and are the guarantee of system circuit stability.

Of course, in pursuit of higher power density, manufacturers are also innovating topological circuits to help user solutions achieve smaller volumes, which is the main way to improve power density. In this process, passive components are the main optimization points, especially the inductance and capacitance, which are closely related to the integration level and switching frequency of the device.

In terms of device integration, devices with advanced gate drivers can significantly reduce the loop inductance in the topology circuit, and the capacitors integrated in some devices can also reduce the loop inductance; in addition, in the form of 3D stacking, the capacitance and The inductor is directly integrated inside the device, which can significantly simplify the topology circuit and system circuit. Therefore, when the selected power management device is a high-integration device, the reduction in the number of passive devices or the reduction in volume will make the user's solution have obvious advantages in power density.

In terms of switching frequency, higher switching frequency not only means better energy efficiency, but also less energy is stored and released per switching cycle, the inductance and output capacitance can be reduced, which in turn reduces the topology circuit and system circuit. Small program size.

It should be noted that when users evaluate the performance of power management devices, they cannot roughly judge their needs through the process, operating frequency, power consumption, GPIO abundance, etc. which chip. For power management devices, the corresponding development tools are a shortcut to accurately grasp the device performance.

Get a Quick Look at Power Management Devices

Next, let's take a look at the practical difficulties that engineers will encounter when selecting power management devices through specific products, and the important role played by development tools.

voltage regulator and its rich assortment

As a device designed to automatically maintain a constant voltage, I believe that engineers and friends are no strangers to voltage regulators. The voltage regulator can efficiently convert the input voltage into the required output voltage, and has the functions of boosting, bucking and regulating. In terms of product classification, voltage regulators include switching regulators, linear regulators, and regulator modules that integrate DC-DC controllers, power transistors, input and output capacitors, compensation components, and inductors in one package. Under each type, there will be rich sub-series, such as switching regulators, there will be boost regulators, step-down regulators and inverting regulators.

When we finally select a voltage regulator through the selection of product parameters, how do we determine that it is what we need? How to have an accurate control over the performance of this regulator?

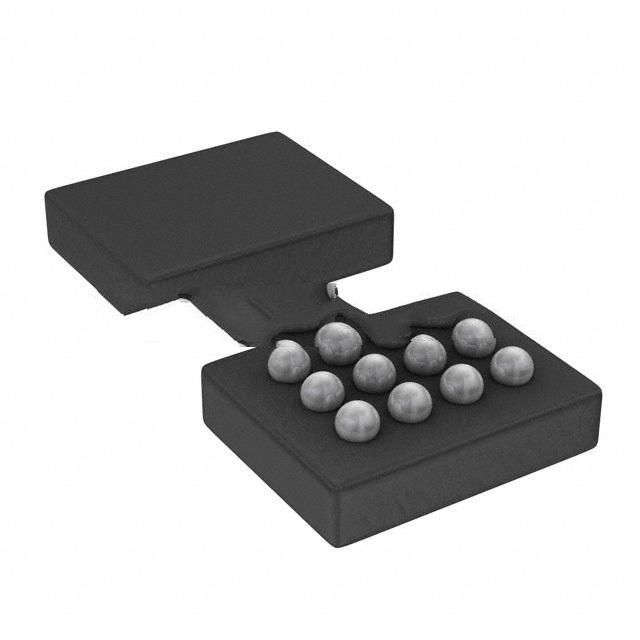

For example, when we selected Mouser Electronics' LTC3310HV#WPBF step-down switching regulator from manufacturer ADI, which has an output voltage range of 500 mV-5.5 V and an input voltage range of 2.25V-5.5 V , the output current is 10A, and the switching frequency is 5 MHz. Obviously, this device is a switching regulator with dynamically adjustable input and output voltages, how would it perform when placed in a voltage regulator circuit?