What does the color of the pcb board represent? Determine the surface process by the color of the pad

What does the color of the pcb board represent? Determine the surface process by the color of the pad

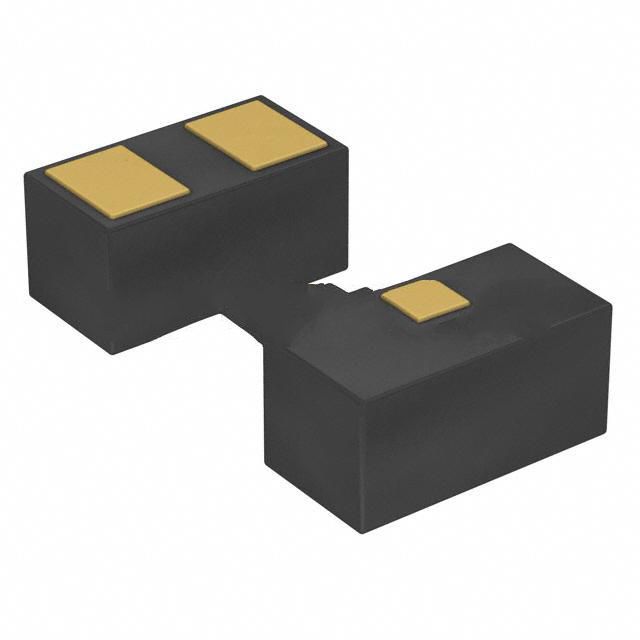

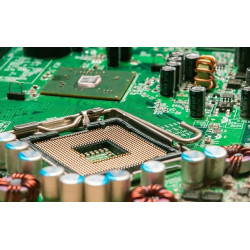

With the rapid development of electronic technology, the process requirements of pcb circuit boards in each industry are different. For example, in the circuit boards of mobile phones and computers, there are gold and copper. Therefore, the recycling price of waste circuit boards is much more expensive than selling waste paper, glass bottles, and scrap iron. From the surface, the outer layer of the circuit board mainly has three colors: gold, silver, light red. Gold is the most expensive, silver is the cheapest, and light red is the cheapest.

From the color, it can be seen whether the manufacturer has cut corners or not. In addition, the circuit inside the circuit board is mainly pure copper. If it is exposed to the air, it is easy to be oxidized, and the outer layer must have the above protective layer. Some people say that the golden color is copper, but that is not true.

What does the color of the pcb board represent? Determine the surface process by the color of the pad

gold

The most expensive gold is real gold. Although only a thin layer, it also accounts for nearly 10% of the cost of the circuit board. Gold is used for two purposes, one is to facilitate welding, and the other is to prevent corrosion. The gold-plated layer is widely used in the component pads, gold fingers, connector shrapnel and other positions of the circuit board. If you find that some boards are all silver, you've cut corners, which is called "costdown" in the industry term. Most mobile phone motherboards are gold-plated boards, while computer motherboards, audio and small digital circuit boards are generally not gold-plated boards.

silver

Is the silver one silver? Of course not, it's tin. The silver board is called spray tin board. Spraying a layer of tin on the outer layer of the copper circuit can also help with soldering. But it cannot provide long-term contact reliability like gold. The tin-sprayed board has no effect on the components that have been soldered, but the reliability of the pads exposed to the air for a long time is not enough, such as ground pads, pin sockets, etc. Long-term use is easy to oxidize and rust, resulting in poor contact. The circuit boards of small digital products, without exception, are spray tin boards. There's only one reason: cheap.

light red

OSP, organic flux film. Because it is organic, not metal, it is cheaper than tin spraying. The only function of this organic film is to ensure that the inner copper foil will not be oxidized before soldering. As soon as it is heated during soldering, the film volatilizes. Solder is able to solder copper wires and components together. However, it is not resistant to corrosion. An OSP circuit board cannot be soldered after being exposed to the air for ten days. Many computer motherboards use the OSP process. Because the area of the circuit board is too large, gold plating cannot be used.

By reading the above content, you should have a preliminary understanding of the color of the pcb board. At the same time, I also hope that you will make a good summary in the learning process, so as to continuously improve your professional level.