BMP280 vs HSCDRRN010MDSA3

| Part Number |

|

|

| Category | Pressure Sensors, Transducers | Pressure Sensors, Transducers |

| Manufacturer | Bosch Sensortec | Honeywell Sensing and Productivity Solutions |

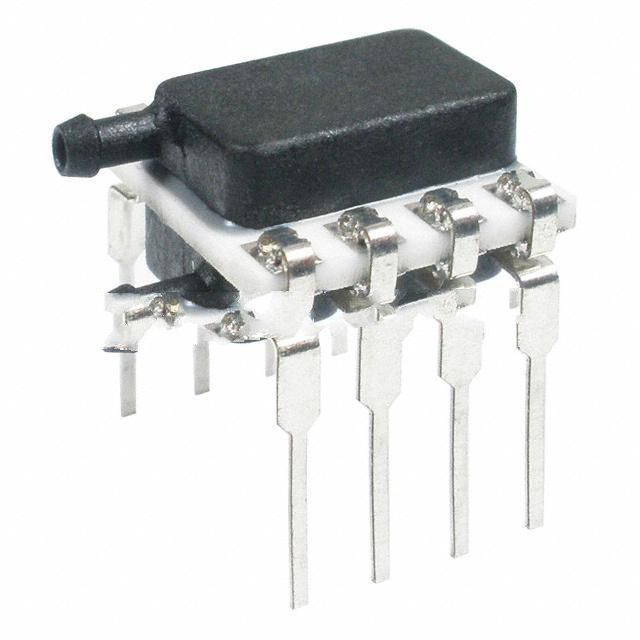

| Description | SENSOR PRESSURE ABS | SENSOR PRES 10MBAR DIFF 3.3V DIP |

| Package | 8-SMD | 8-DIP (0.524", 13.30mm), Dual Ports, Same Side |

| Series | - | TruStability? HSC |

| Features | Standby Mode | Amplified Output, Temperature Compensated |

| Voltage - Supply | 1.71 V ~ 3.6 V | 3.27 V ~ 3.33 V |

| Operating Temperature | -40°C ~ 85°C | -20°C ~ 85°C |

| Package / Case | 8-SMD | 8-DIP (0.524", 13.30mm), Dual Ports, Same Side |

| Supplier Device Package | 8-SMD | 8-DIP |

| Output | 16b | 12 b |

| Accuracy | ±0.0145 PSI (±0.1 kPa) | ±0.25% |

| Output Type | I²C, SPI | SPI |

| Termination Style | SMD (SMT) Tab | PC Pin |

| Pressure Type | Absolute | Differential |

| Operating Pressure | 4.35 PSI ~ 15.95 PSI (30 kPa ~ 110 kPa) | ±0.15 PSI (±1 kPa) |

| Maximum Pressure | 290.08 PSI (2000 kPa) | ±10.88 PSI (±75 kPa) |

| Port Style | - | Barbed |

| Port Size | - | Male - 0.08" (1.93mm) Tube, Dual |

-

1. Is a transducer a sensor?

A transducer is not a sensor. Although both sensors and transducers are devices for measuring physical quantities, they have obvious differences in definition and application.

Definition and function

Sensor: A sensor is a device that converts non-electrical signals into electrical signals. It is usually used to convert physical quantities (such as temperature, pressure, humidity, light intensity, etc.) into electrical signals. Sensors are widely used in industry, medical care, environmental monitoring and other fields.

Transducer: A transducer is a device that converts one form of energy into another form. It can convert any form of physical quantity (such as pressure, force, torque, displacement, sound, light, heat, etc.) into electrical signals or other forms of energy output. Transducers are widely used in the control, measurement and detection of various industrial processes.

-

2. Application field

Sensor: Mainly used for industrial process control and monitoring, equipment control and monitoring in the fields of automobiles, machinery, electronics, medical equipment, aerospace, etc., as well as environmental monitoring and weather forecasting.

Transducers: Mainly used in exploration and production processes in the fields of ocean, petroleum, aviation, energy, etc., engineering measurement and control fields (such as monitoring and control of structures such as buildings, bridges and tunnels), scientific research fields (such as physics, chemistry, biology, etc.), and music and art fields (such as electronic musical instruments and sound amplifiers). -

3. What is the difference between a transducer and a sensor?

Sensors and transducers are two different concepts. A sensor is a device that converts non-electrical signals into electrical signals, while a transducer is a device that converts one form of energy into another form.

1. Definition of sensors and transducers

Both sensors and transducers are devices that measure physical quantities.

A sensor is a device that converts non-electrical signals into electrical signals, and is usually used to convert physical quantities into electrical signals, such as temperature, pressure, humidity, light intensity, etc. Sensors are widely used in industry, medical care, environmental monitoring and other fields.

A transducer is a device that converts one form of energy into another. A transducer can convert any form of physical quantity (such as pressure, force, torque, displacement, sound, light, heat, etc.) into electrical signals or other forms of energy output. The application field of transducers is also very wide, and they are often used to detect, control and measure various industrial processes.

2. The difference between sensors and transducers

The main difference between sensors and transducers is which signal they convert into which signal. Sensors mainly convert non-electrical signals into electrical signals, while transducers can convert any form of signal into other forms of energy, such as electrical signals or mechanical motion.

In addition, the application fields of sensors and transducers are also different. Sensors are mainly used to detect, monitor and measure various physical quantities, such as temperature, pressure, humidity, light intensity, etc.; while transducers are widely used to control, measure and detect various industrial processes, such as flow, speed, force, pressure and displacement, etc.

3. Application fields of sensors and transducers

Sensors and transducers have a wide range of applications. Sensors are usually used in the following fields:

1. Industrial process control and monitoring.

2. Equipment control and monitoring in the fields of automobiles, machinery, electronics, medical equipment, aerospace, etc.

3. Environmental monitoring and weather forecasting.

4. Home automation and smart home fields.

Transducers are mainly used in the following fields:

1. Exploration and production processes in the fields of ocean, petroleum, aviation, energy, etc.

2. Engineering measurement and control fields, such as monitoring and control of structures such as buildings, bridges and tunnels.

3. Scientific research fields, such as physics, chemistry, biology, etc.

4. Music and art fields, such as electronic musical instruments and sound amplifiers, etc.

-

4. What is the difference between sensors and actuators?

The main difference between sensors and actuators lies in their functions, design principles and application scenarios.

Function and design principle

Sensor: A sensor is a device that converts various physical quantities (such as temperature, pressure, light intensity, etc.) into easy-to-process electrical signals. Its main function is to detect and collect physical quantities in the environment, and convert these physical quantities into electrical signal output for further processing and analysis.

Actuator: An actuator is a device that converts electrical signals, air pressure, hydraulic pressure and other energies into physical motion. Its main function is to perform corresponding action control according to the received electrical signal, such as controlling the movement of the robot, adjusting the cutting of the machine tool, etc.

Application scenarios

Sensors: Sensors are usually used in areas that require monitoring environmental information, controlling automation equipment, adjusting motion control systems, such as smart homes, aircraft, robots, etc.

Actuators: Actuators are used to adjust control systems, convert energy, complete mechanical work, etc., such as hydraulic pumps driven by electric motors, pneumatic control valves, etc.