T491A155M016AT vs T491A105K016AT

| Part Number |

|

|

| Category | Tantalum Capacitors | Tantalum Capacitors |

| Manufacturer | KEMET | KEMET |

| Description | CAP TANT 1.5UF 20% 16V 1206 | CAP TANT 1UF 10% 16V 1206 |

| Package | Tape & Reel (TR) | Cut Tape (CT) |

| Series | T491 | T491 |

| Type | Molded | Molded |

| Features | General Purpose | General Purpose |

| Operating Temperature | -55°C ~ 125°C | -55°C ~ 125°C |

| Mounting Type | Surface Mount | Surface Mount |

| Package / Case | 1206 (3216 Metric) | 1206 (3216 Metric) |

| Tolerance | ±20% | ±10% |

| Size / Dimension | 0.126" L x 0.063" W (3.20mm x 1.60mm) | 0.126" L x 0.063" W (3.20mm x 1.60mm) |

| Voltage - Rated | 16 V | 16 V |

| Lead Spacing | - | - |

| Ratings | - | - |

| Height - Seated (Max) | 0.071\" (1.80mm) | 0.071\" (1.80mm) |

| Capacitance | 1.5 µF | 1 µF |

| ESR (Equivalent Series Resistance) | 8Ohm | 10Ohm |

| Lifetime @ Temp. | 2000 Hrs @ 125°C | 2000 Hrs @ 125°C |

| Failure Rate | - | - |

| Manufacturer Size Code | A | A |

-

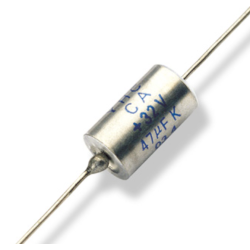

1. Difference between ordinary capacitors and tantalum capacitors

Material: Ordinary capacitors can be aluminum electrolytic capacitors, ceramic capacitors, etc.; while tantalum capacitors use metal tantalum as anode material.

Performance: Generally, tantalum capacitors have better temperature stability and higher capacity-to-volume ratio.

Application range: Due to its performance characteristics, tantalum capacitors are often used in miniaturized electronic products that require high reliability. -

2. Can I use ceramic capacitors instead of tantalum capacitors?

It depends on the specific situation. If the size, ESR requirements are not high and a specific capacitance value is not required, you can consider replacing it.

But be aware that there are differences in physical properties between the two, and direct replacement may affect the working state of the circuit. -

3. What special precautions must be taken when installing tantalum capacitors?

Ensure the correct polarity connection.

Be careful not to exceed the rated voltage.

Use appropriate fuses or other protective devices to prevent overcurrent.

Consider heat dissipation design to avoid local overheating. -

4. What causes tantalum capacitors to burn out?

Common causes include applying a voltage exceeding the maximum allowable value, excessive current, high ambient temperature, and manufacturing defects.