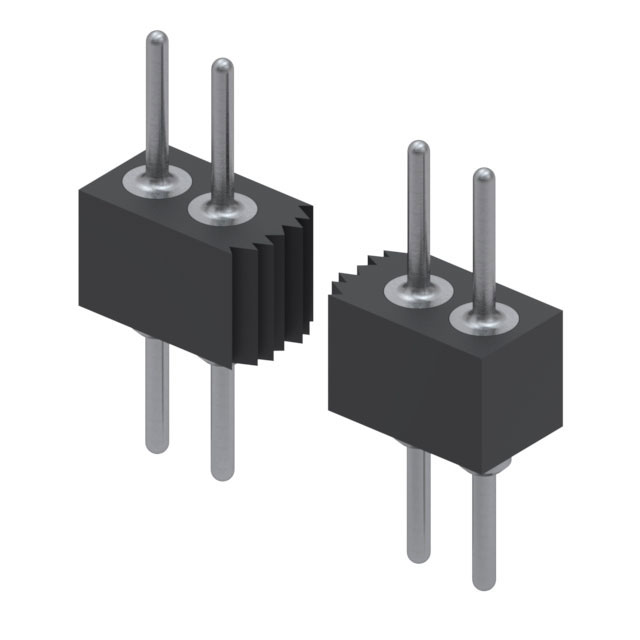

0878322620 Product Introduction:

Molex Part Number 0878322620(Rectangular Connectors - Headers, Male Pins), developed and manufactured by Molex, distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

0878322620 is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately sales@jinftry.com Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

Rectangular Connectors - Headers, Male Pins are key components that enable signal or power connections between circuits. It consists of an insulated base and multiple metal pins arranged in a rectangular array, which are fixed to the base by crimping, welding, or threading. The needle holder serves as the female end, while the male pin serves as the corresponding male end, and the two are electrically connected through precise coordination. In terms of design principles, rectangular connectors emphasize the characteristics of high density, high reliability, and easy insertion and removal, and are widely used in situations that require stable and efficient signal transmission. Its characteristics include low contact resistance, high withstand voltage, wear resistance, and resistance to electromagnetic interference.

Application

Rectangular Connectors - Headers, Male Pins are widely used in various electronic devices, especially in computer hardware, communication equipment, industrial automation control and other fields. In the field of computer hardware, they are used to connect core components such as motherboards, graphics cards, and memory modules, ensuring high-speed data transmission and stable system operation. In communication equipment, rectangular connectors are used to connect circuit boards, modules, antennas, etc., supporting high-speed signal transmission and complex circuit layouts. In industrial automation control systems, rectangular connectors serve as a bridge between sensors, actuators, and controllers to achieve precise control and data feedback.

FAQ about Rectangular Connectors - Headers, Male Pins

-

1. Rectangular connector standards

1. Rated voltage and rated current: The rated voltage and rated current of rectangular connectors are important indicators to measure their performance.

For example, the GB/T 42207.5-2022 standard stipulates that the rated voltage of rectangular connectors is DC 250V and the rated current is 30A, while another standard stipulates a rectangular connector with a rated voltage of DC 400V and a rated current of 16A.

2. Design and structure of connectors: The design of rectangular connectors includes its jack design, termination form, fixing method, etc.

For example, the CY23, CRM, and J36 series rectangular electrical connectors use termination forms such as hyperbolic wire spring jacks and printed circuit board soldering, and provide a variety of fixing forms, such as threaded guide pins and guide sleeves with locking functions, as well as riveting, threaded fastening and other fixing forms.

3. Materials and manufacturing standards: The manufacturing materials and standards of rectangular connectors are also important guarantees of their performance.

For example, the insulator of the connector can be made of LCP material or PA66 material, which has good temperature range and stability and is suitable for different application environments. The material selection of the connector shell depends on the specific needs of the application, such as plastic, metal, alloy or glass fiber reinforced plastic, which has good insulation performance, wear resistance, corrosion resistance and mechanical strength.

-

2. What are the types of rectangular connectors?

Pin-type rectangular connector: This is the most common type of rectangular connector. The metal pin is inserted into the interface hole and rotated to tighten to achieve conductive connection.

Snap-on rectangular connector: It is fixed with self-locking mechanisms such as spring sheets or clips and is suitable for use in vibration environments.

Patch-type rectangular connector (SMT type): Suitable for use in surface mount technology (SMT), convenient and fast.

Board-to-board rectangular connector: Mainly used for the interconnection of board-level and system-level circuits, with high-density connection, low plug-in and pull-out times, and easy maintenance.

Wire-to-board rectangular connector: Suitable for connecting internal signals and power of equipment, can withstand high current and high temperature environments, and has the advantages of easy installation and convenient maintenance.

-

3. Common packaging methods for rectangular connectors

1. Panel-mounted packaging

Panel-mounted packaging is the most common form of rectangular connector, which allows the connector to be directly fixed to the housing or panel of the device. This packaging method is usually achieved by screw locking, snap-on fixing or crimping to ensure a stable connection between the connector and the panel. The advantages of panel-mounted packaging are that it is easy and quick to install, easy to maintain and replace, and can provide good mechanical strength and protection level. It is suitable for scenarios that require frequent plugging and unplugging or high protection requirements, such as industrial control equipment, communication equipment, medical equipment, etc.

2. Printed board mounted packaging

Printed board mounted packaging is another widely used rectangular connector packaging method. It directly solders the connector on the PCB (printed circuit board) and realizes electrical connection through pins or pads. This packaging method has the advantages of small size, light weight, flexible layout, etc., which can save space to the maximum extent and improve the integration of circuit boards. It is widely used in computers, consumer electronics, automotive electronics and other fields, especially in occasions with extremely high space requirements, such as mobile phones, tablets and other portable devices.

3. Needle seat and socket combined packaging

The needle seat and socket combined packaging is a packaging form in which the two parts of the connector (needle seat and socket) are designed separately, and then the electrical connection is realized by plugging. This packaging method has the characteristics of easy plugging and unplugging, easy replacement and upgrading, and is particularly suitable for scenarios where modules need to be frequently replaced or systems need to be upgraded. For example, in the fields of test equipment, modular data centers, etc., the combined package of pin header and socket can significantly improve the flexibility and maintainability of the system.

4. Mixed package

With the continuous development of electronic technology, a single packaging method has been difficult to meet the complex and changing application requirements. Therefore, mixed package came into being, which combines multiple packaging methods to form a comprehensive solution. For example, combining panel mounting with printed circuit board mounting not only ensures the stability of the connector, but also improves the integration of the circuit board; or combining the combination of pin header and socket with modular design to achieve a more flexible and changeable system configuration.

The design of mixed package needs to comprehensively consider various factors, including spatial layout, electrical performance, mechanical strength, cost-effectiveness, etc., to seek the best design solution. At the same time, it is also necessary to pay attention to the compatibility and interoperability between different packaging methods to ensure the overall performance and stability of the system.

5. Special environment adaptability package

In some special environments, such as high temperature, low temperature, high humidity, strong electromagnetic interference, etc., higher requirements are put forward for the packaging method of rectangular connectors. To this end, a variety of special environmental adaptability packages have been developed, such as high temperature resistant packages, waterproof packages, and anti-electromagnetic interference packages. These packaging methods improve the environmental adaptability of connectors by using special materials and optimizing structural design, ensuring that they can still work stably and reliably in harsh environments.

Lead free / RoHS Compliant

Lead free / RoHS Compliant