Bourns Inc. 2035-35-BLF

- 2035-35-BLF

- Bourns Inc.

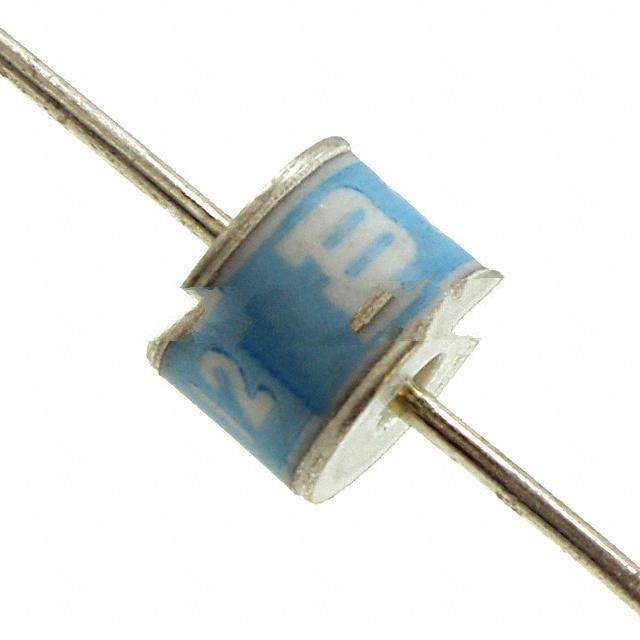

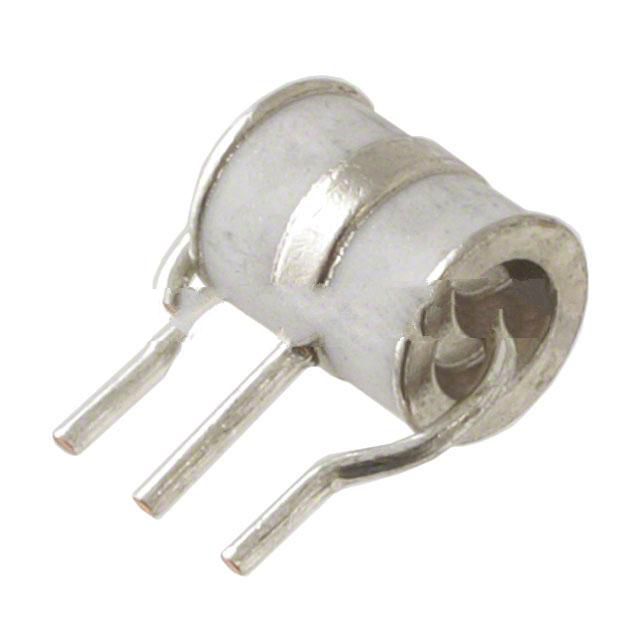

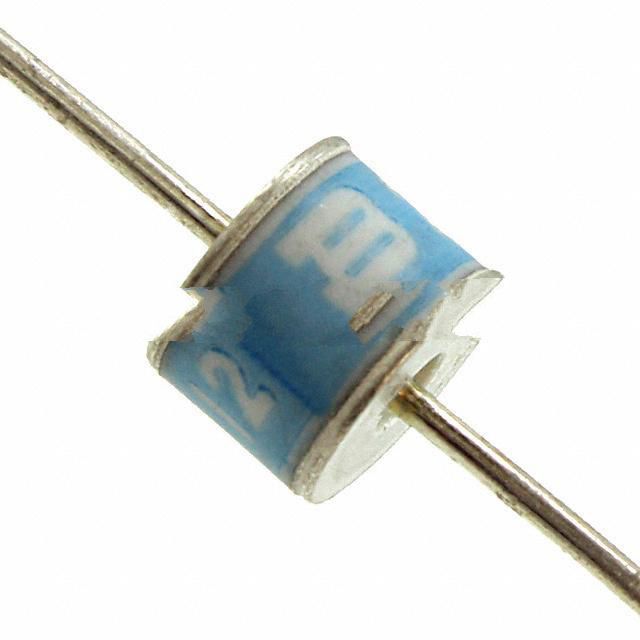

- GDT 350V 15% 5KA THROUGH HOLE

- Gas Discharge Tube Arresters (GDT)

- 2035-35-BLF Datasheet

- Axial Cylinder

- Axial Cylinder

-

Lead free / RoHS Compliant

Lead free / RoHS Compliant - 14515

- Spot Inventory / Athorized Dstributor / Factory Excess Stock

- 1 year quality assurance 》

- Click to get rates

What is 2035-35-BLF

Bourns Inc. Part Number 2035-35-BLF(Gas Discharge Tube Arresters (GDT)), developed and manufactured by Bourns Inc., distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

2035-35-BLF is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately [email protected] Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

2035-35-BLF Specifications

- Part Number2035-35-BLF

- CategoryGas Discharge Tube Arresters (GDT)

- ManufacturerBourns Inc.

- DescriptionGDT 350V 15% 5KA THROUGH HOLE

- PackageAxial Cylinder

- Series2035

- Mounting TypeThrough Hole

- Package / CaseAxial Cylinder

- Tolerance±15%

- Number of Poles2

- Voltage - DC Spark Over (Nom)350V

- Impulse Discharge Current (8/20µs)5000A (5kA)

- Fail ShortNo

Application of 2035-35-BLF

2035-35-BLF Datasheet

2035-35-BLF Datasheet , Axial Cylinder,2035,Through Hole,Axial Cylinder,±15%,2,350V,5000A (5kA),No

2035-35-BLF Classification

Gas Discharge Tube Arresters (GDT)

FAQ about Gas Discharge Tube Arresters (GDT)

-

1. What is a GDT gas discharge tube?

A GDT gas discharge tube (Gas Discharge Tube) is a device used to protect electronic equipment from transient voltage damage. It is mainly composed of one or more discharge gaps, sealed in a ceramic cavity or glass tube filled with inert gas. Under normal working conditions, the GDT maintains a high resistance state; when the voltage exceeds its breakdown voltage, the gas in the gas discharge tube is ionized to form a conductive path, which introduces the surge current into the ground, thereby protecting the equipment. Once the overvoltage disappears, the GDT returns to a high impedance state and waits for the next shock.

Working Principle

The working principle of GDT is based on the gas discharge phenomenon. Under normal operating voltage, the inert gas inside the GDT remains non-conductive and the device is in a high impedance state. When the voltage reaches or exceeds its breakdown voltage, the gas ionizes to form a plasma path, causing the GDT to present a low impedance state, directing the surge current into the ground, thereby protecting the device. After the overvoltage disappears, the GDT returns to a high impedance state. -

2. What is the difference between GDT and MOV?

GDT (gas discharge tube) and MOV (varistor) each have their own characteristics and applicable scenarios in circuit protection.

Working Principle and Characteristics

GDT: GDT is a switching overvoltage protection component with the characteristics of large flow rate, large inter-electrode insulation resistance, slow response speed and small parasitic capacitance. It is often used in high-frequency electronic circuit protection, especially as the first or second level protection in multi-level protection circuits. The working principle of GDT is to limit the voltage through gas discharge. When the voltage reaches a certain threshold, the gas in the gas discharge tube is ionized, thereby conducting the current and protecting the subsequent circuit.

MOV: MOV is a clamping type overvoltage protection component with large flow rate, slow response speed and large parasitic capacitance. MOV uses its nonlinear characteristics to clamp the voltage to a relatively fixed voltage value when overvoltage occurs, thereby protecting the subsequent circuit. The main materials of MOV are divalent element zinc and hexavalent element oxygen, and its nonlinear characteristics are used to limit the voltage. -

3. How does GDT work?

The working principle of GDT (gas discharge tube) is mainly based on its electrical characteristics, which are determined by the type of gas, pressure and electrode distance. The GDT is filled with inert gas (such as neon or argon) and maintains a certain pressure. When the voltage across the GDT rises to a value greater than its discharge voltage, the gas begins to ionize, causing the discharge tube to conduct, changing from a high impedance state to a low impedance state, thereby rapidly reducing the voltage across the two ends.

The working process of GDT can be divided into the following stages:

Insulation state: When there is no surge, GDT is in an open circuit state, which is equivalent to a high-impedance insulator with a very large resistance (usually greater than 1000 megohms), almost no leakage current or very small leakage current.

Discharge state: When the voltage across the GDT rises to a value greater than its discharge voltage, the gas begins to ionize and the discharge tube is turned on. At this time, the GDT changes from a high-impedance state to a low-impedance state, causing the voltage across its two ends to drop rapidly, usually by tens of volts.

Follow-current effect: Due to the follow-current characteristics of the gas discharge tube, even if the surge voltage disappears, as long as a certain voltage (usually above 15V) is maintained at both ends, the GDT will remain in the on state and continue to conduct electricity.

The application scenarios of GDT mainly include lightning surge protection, which is suitable for lightning protection of AC and DC power supplies and signal circuits. It can quickly turn on when a surge arrives, limit the voltage peak, and protect the connected electronic equipment from damage.

We are a professional PCB manufacturer who offers comprehensive PCB manufacturing services including: professional Ceramic PCB HDI PCB Heavy Copper PCB High-TG PCB High Speed PCB High Frequency PCB Metal Core PCB PCB fabrication and PCB assembly, providing fast turnaround prototypes for high-end products.

• Prompt Responsiveness

• Guaranteed Quality

• Global Access

• Competitive Market Price

• One-Stop support services of supply chain

Jinftry, Your most trustworthy component supplier, welcome to send us the inquiry, thank you!

Do you have any questions about 2035-35-BLF ?

Feel free to contact us: