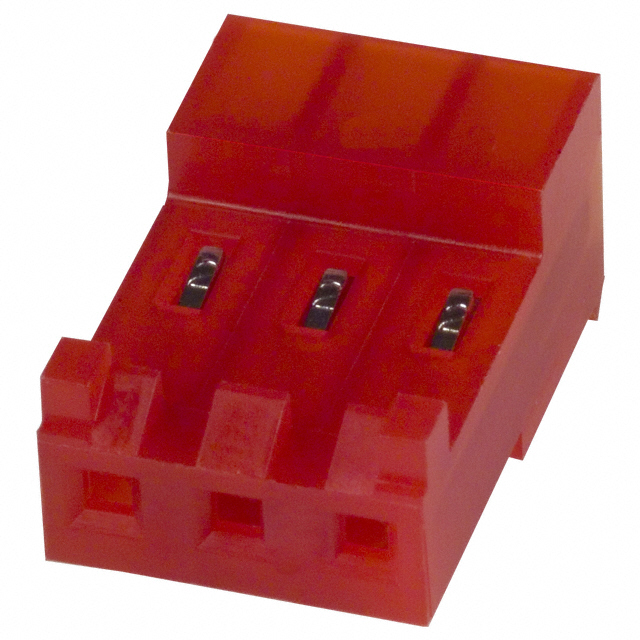

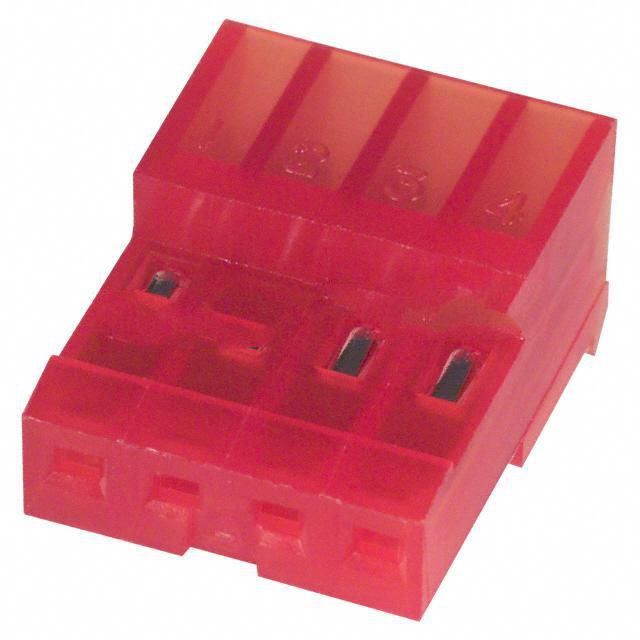

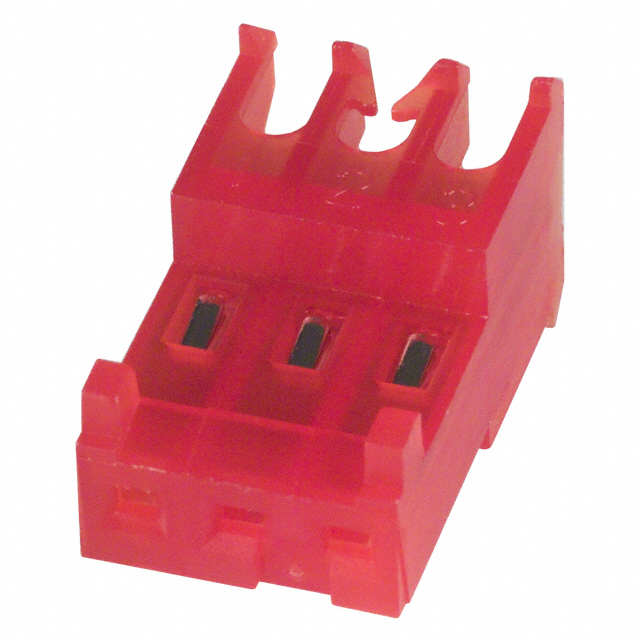

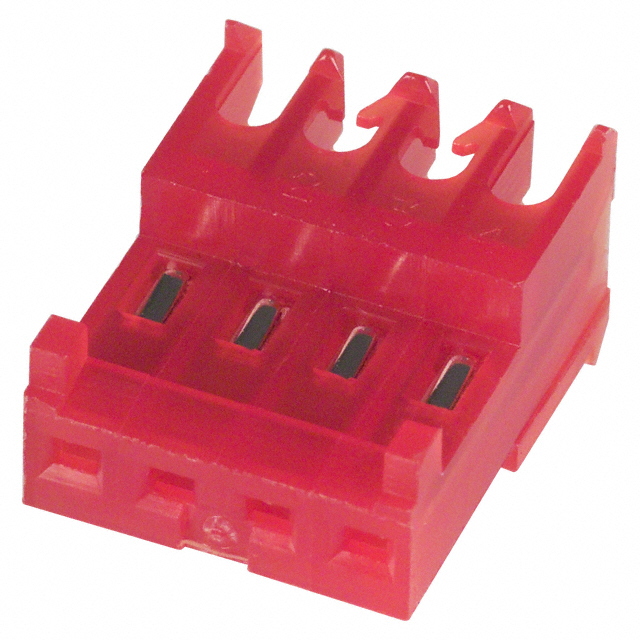

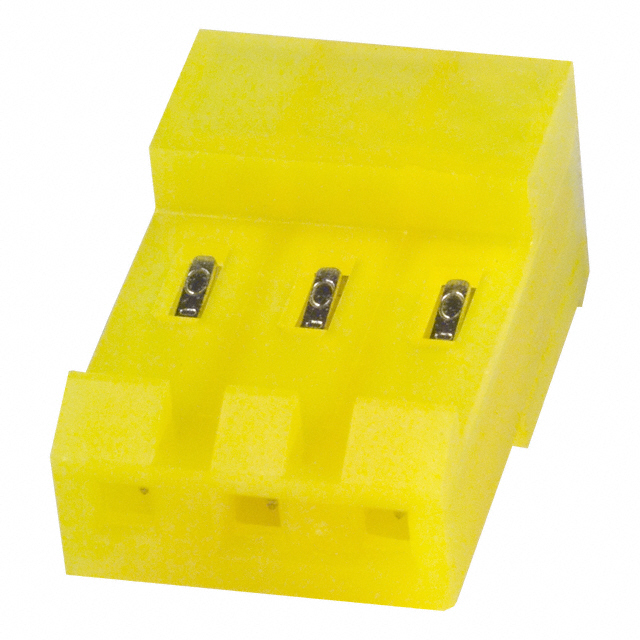

353293-5 Product Introduction:

TE Connectivity AMP Connectors Part Number 353293-5(Rectangular Connectors - Free Hanging, Panel Mount), developed and manufactured by TE Connectivity AMP Connectors, distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

353293-5 is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately sales@jinftry.com Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

Rectangular Connectors - Free Hanging, Panel Mount are two types of connectors that enable efficient and flexible connections between electronic devices and systems. The free hanging type is suitable for scenarios that require flexible wiring or limited space. It is directly suspended and connected through cables for easy installation and maintenance. The panel installation type is designed specifically for fixed installation on equipment panels, secured with screws or other fasteners to ensure a stable and reliable connection. This type of connector typically consists of an insulated housing, conductive contacts, locking mechanisms, and protective devices, among other components. It offers advantages such as flexible installation, high transmission rate, and low contact resistance.

Application

Rectangular Connectors - Free Hanging, Panel Mount are widely used in various fields. In the communication industry, they are commonly used for internal and external connections of devices such as base stations, switches, routers, etc. In the field of industrial automation, rectangular connectors serve as a bridge between devices such as PLCs, sensors, and actuators. In data center servers, rectangular connectors installed on panels are used to connect servers to power distribution units, achieving efficient and stable power supply. In automotive electronic systems, freely suspended rectangular connectors facilitate flexible layout and quick maintenance of complex wiring harnesses inside the vehicle.

FAQ about Rectangular Connectors - Free Hanging, Panel Mount

-

1. What are the types of rectangular connectors?

1. Pin-type rectangular connector: This is the most common type of rectangular connector. The metal pin is inserted into the interface hole and rotated to tighten to achieve conductive connection.

2. Snap-on rectangular connector: It is fixed with self-locking mechanisms such as spring sheets or clips, and is suitable for use in vibration environments.

3. SMD rectangular connector (SMT type): It is suitable for use in surface mount technology (SMT), which is convenient and fast.

4. Board-to-board rectangular connector: Mainly used for interconnection of board-level and system-level circuits, with the characteristics of high-density connection, low plug-in and pull-out times, and easy maintenance.

5. Wire-to-board rectangular connector: Suitable for the connection of internal signals and power of equipment, can withstand high current and high temperature environments, and has the advantages of easy installation and convenient maintenance.

-

2. Operation Guide for Rectangular Connectors?

1. To ensure reliable connection of the product, ensure that the connector is properly plugged in during use. Do not forcefully insert if any abnormality is found during insertion.

2. Connectors that are not fully inserted or not locked cannot be powered on.

3. The derating of the main technical parameters of the product (see the rectangular connector product sample manual) should be clarified according to different application conditions to improve the reliability of use.

4. The rectangular electrical connector is a short-shell connector that does not have the function of preventing oblique insertion. When inserting, the direction should be aligned first and then pushed in slowly, because it takes time for the twist needle to automatically find the correct position. It is recommended to observe with your eyes when plugging or separating the connector, operate carefully, prevent the product from being excessively deflected, and try not to use the left and right shaking method to pull it out. In particular, excessive deflection at the moment of plugging or separating should be avoided, otherwise it may cause damage to the pins, sockets, shells and other parts.

5. During use, the root of the cable should be avoided from being stressed to prevent the cable from coming out or breaking.

6. For sealed rectangular electrical connector products supported by glass insulators, the welding terminals should not be moved arbitrarily during welding, and they should not be shaken left and right when unplugged. Also, be careful to handle with care.

7. For applications where plugging and unplugging are frequent, converters, transfer cables or anti-slant plug connectors can be used when necessary.

8. For connectors that require soldering, damage to the connector due to excessive soldering iron temperature or long soldering time should be avoided.

9. The connector should be plugged in or dust-proof when placed.

10. The accessories of the connector should be installed with matching installation tools to avoid excessive torque damaging the screws or nuts. When the installation accessories need to be prevented from loosening, it is recommended to take necessary measures to prevent loosening (such as adding elastic washers, etc.).

-

3. How to connect rectangular connectors?

1. Crimping: It has high mechanical strength, good electrical performance, and high reliability.

2. Welding: It has the advantage of simple operation. However, it is easy to form a cold solder joint that is not easy to find due to welding methods, operating space, etc.

Lead free / RoHS Compliant

Lead free / RoHS Compliant