3M 4630-6001

- 4630-6001

- 3M

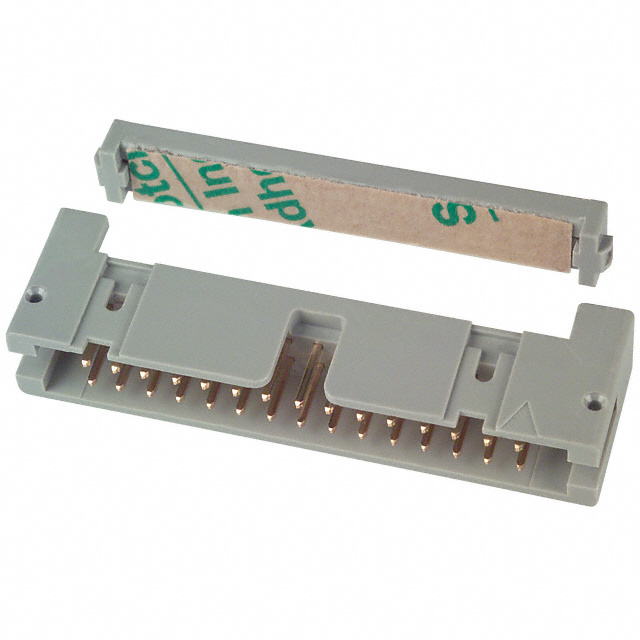

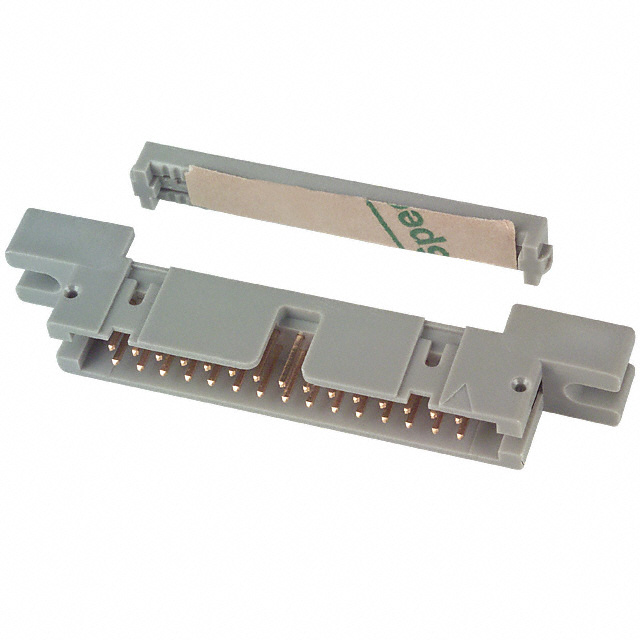

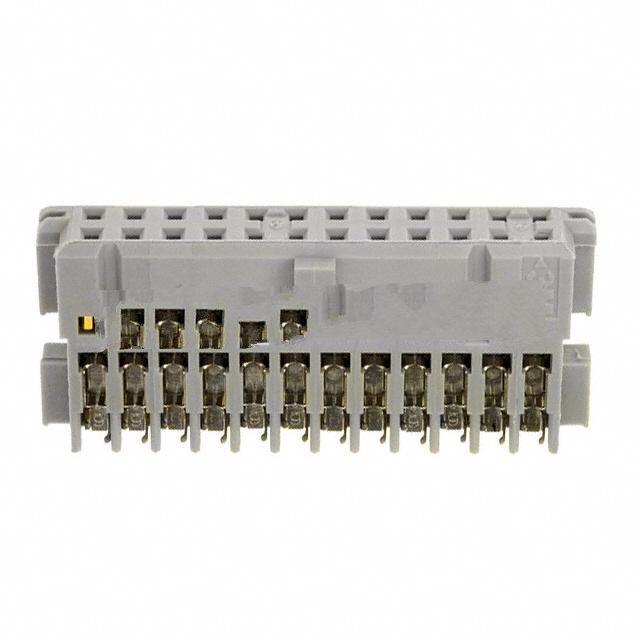

- PLUG CONNECTOR 30 POS W/O FLANGE

- Rectangular Connectors - Free Hanging, Panel Mount

- 4630-6001 Datasheet

- -

- -

-

Lead free / RoHS Compliant

Lead free / RoHS Compliant - 1171

- Spot Inventory / Athorized Dstributor / Factory Excess Stock

- 1 year quality assurance 》

- Click to get rates

What is 4630-6001

3M Part Number 4630-6001(Rectangular Connectors - Free Hanging, Panel Mount), developed and manufactured by 3M, distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

4630-6001 is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately [email protected] Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

4630-6001 Specifications

- Part Number4630-6001

- CategoryRectangular Connectors - Free Hanging, Panel Mount

- Manufacturer3M

- DescriptionPLUG CONNECTOR 30 POS W/O FLANGE

- Package-

- Series4600

- FeaturesFeed Through

- Mounting TypeFree Hanging (In-Line)

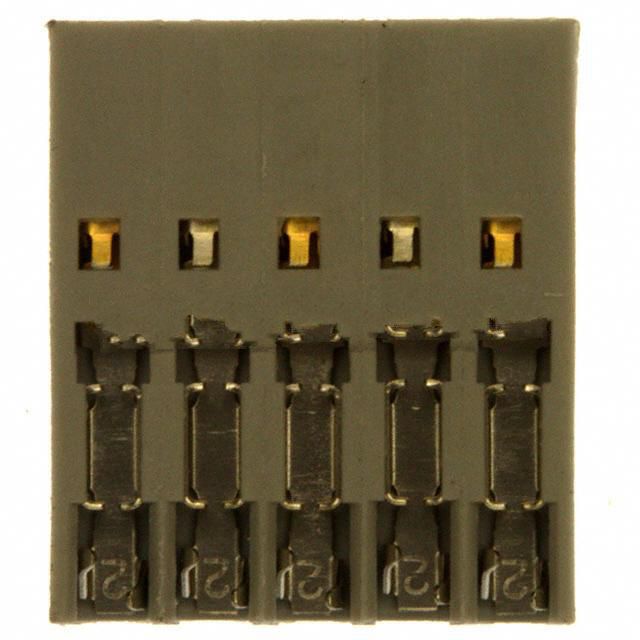

- Contact FinishGold

- ColorGray

- Number of Positions30

- Pitch0.100" (2.54mm)

- Connector TypePlug

- Wire Gauge26-28 AWG, Stranded or Solid

- Contact Finish Thickness30µin (0.76µm)

- Number of Rows2

- Contact TypeMale Pin

- Row Spacing0.100" (2.54mm)

- Cable TerminationIDC

- Wire TypeDiscrete or Ribbon Cable

Application of 4630-6001

4630-6001 Datasheet

4630-6001 Datasheet , 4600,Feed Through,Free Hanging (In-Line),Gold,Gray,30,0.100" (2.54mm),Plug,26-28 AWG, Stranded or Solid,30µin (0.76µm),2,Male Pin,0.100" (2.54mm),IDC,Discrete or Ribbon Cable

4630-6001 Classification

Rectangular Connectors - Free Hanging, Panel Mount

FAQ about Rectangular Connectors - Free Hanging, Panel Mount

-

1. Common packaging methods for rectangular connectors?

1. Panel-mounted packaging

Panel-mounted packaging is the most common form of rectangular connector, which allows the connector to be directly fixed to the housing or panel of the device. This packaging method is usually achieved by screw locking, snap-on fixing or crimping to ensure a stable connection between the connector and the panel. The advantages of panel-mounted packaging are easy and quick installation, easy maintenance and replacement, and good mechanical strength and protection level. It is suitable for scenarios that require frequent plugging and unplugging or high protection requirements, such as industrial control equipment, communication equipment, medical equipment, etc.

2. PCB Mounting Package

PCB mounting packaging is another widely used rectangular connector packaging method. It directly solders the connector on the PCB (printed circuit board) and realizes electrical connection through pins or pads. This packaging method has the advantages of small size, light weight, flexible layout, etc., which can save space to the maximum extent and improve the integration of the circuit board. It is widely used in computers, consumer electronics, automotive electronics and other fields, especially in occasions with extremely high space requirements, such as mobile phones, tablets and other portable devices.

3. Pin header and socket combination packaging

The pin header and socket combination packaging is a packaging form in which the two parts of the connector (pin header and socket) are designed separately and then electrically connected by plugging. This packaging method is easy to plug and unplug and easy to replace and upgrade, and is particularly suitable for scenarios where frequent module replacement or system upgrade is required. For example, in the fields of test equipment, modular data centers, etc., the pin header and socket combination packaging can significantly improve the flexibility and maintainability of the system.

4. Mixed packaging

With the continuous development of electronic technology, a single packaging method has been difficult to meet the complex and changing application requirements. Therefore, mixed packaging came into being, which combines multiple packaging methods to form a comprehensive solution. For example, combining panel mounting with printed circuit board mounting not only ensures the stability of the connector, but also improves the integration of the circuit board; or combining the pin and socket combination with modular design to achieve a more flexible and changeable system configuration.

5. Special environmental adaptability packaging

In some special environments, such as high temperature, low temperature, high humidity, strong electromagnetic interference, etc., higher requirements are placed on the packaging method of rectangular connectors. To this end, a variety of special environmental adaptability packages have been developed, such as high temperature resistant packaging, waterproof packaging, anti-electromagnetic interference packaging, etc. These packaging methods improve the environmental adaptability of the connector by using special materials and optimizing structural design, ensuring that it can still work stably and reliably in harsh environments. -

2. Operation Guide for Rectangular Connectors?

1. To ensure reliable connection of the product, ensure that the connector is properly plugged in during use. Do not forcefully insert if any abnormality is found during insertion.

2. Connectors that are not fully inserted or not locked cannot be powered on.

3. The derating of the main technical parameters of the product (see the rectangular connector product sample manual) should be clarified according to different application conditions to improve the reliability of use.

4. The rectangular electrical connector is a short-shell connector that does not have the function of preventing oblique insertion. When inserting, the direction should be aligned first and then pushed in slowly, because it takes time for the twist needle to automatically find the correct position. It is recommended to observe with your eyes when plugging or separating the connector, operate carefully, prevent the product from being excessively deflected, and try not to use the left and right shaking method to pull it out. In particular, excessive deflection at the moment of plugging or separating should be avoided, otherwise it may cause damage to the pins, sockets, shells and other parts.

5. During use, the root of the cable should be avoided from being stressed to prevent the cable from coming out or breaking.

6. For sealed rectangular electrical connector products supported by glass insulators, the welding terminals should not be moved arbitrarily during welding, and they should not be shaken left and right when unplugged. Also, be careful to handle with care.

7. For applications where plugging and unplugging are frequent, converters, transfer cables or anti-slant plug connectors can be used when necessary.

8. For connectors that require soldering, damage to the connector due to excessive soldering iron temperature or long soldering time should be avoided.

9. The connector should be plugged in or dust-proof when placed.

10. The accessories of the connector should be installed with matching installation tools to avoid excessive torque damaging the screws or nuts. When the installation accessories need to be prevented from loosening, it is recommended to take necessary measures to prevent loosening (such as adding elastic washers, etc.). -

3. Types of rectangular connectors?

1. In the past, it was mainly produced by enterprises under the Ministry of Electronics Industry, such as CA, CB, and CD rectangular connectors.

2. Now it is more commonly used, mainly produced by enterprises under the Ministry of Electronics.

3. J-type rectangular connectors, mainly produced by enterprises under the Ministry of Aviation and Aerospace.

4. Rectangular connectors produced according to the national military standard (GJB).

5. Rectangular connectors produced according to the International Electrotechnical Commission (IEC) standard.

We are a professional PCB manufacturer who offers comprehensive PCB manufacturing services including: professional Ceramic PCB HDI PCB Heavy Copper PCB High-TG PCB High Speed PCB High Frequency PCB Metal Core PCB PCB fabrication and PCB assembly, providing fast turnaround prototypes for high-end products.

• Prompt Responsiveness

• Guaranteed Quality

• Global Access

• Competitive Market Price

• One-Stop support services of supply chain

Jinftry, Your most trustworthy component supplier, welcome to send us the inquiry, thank you!

Do you have any questions about 4630-6001 ?

Feel free to contact us: