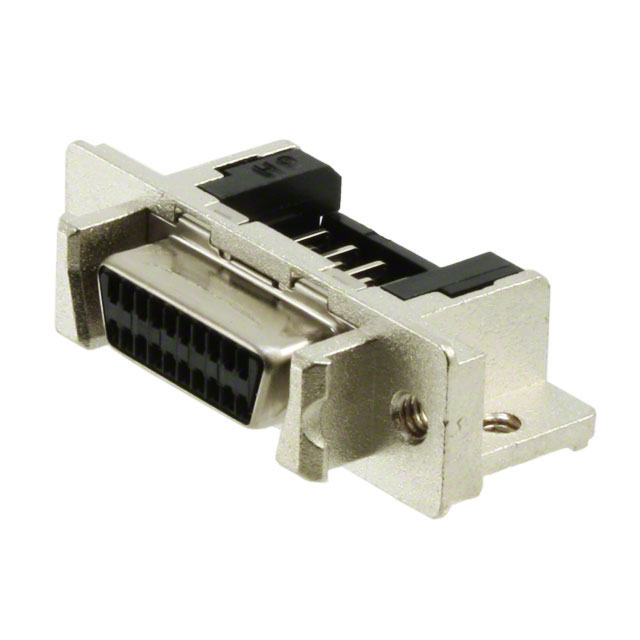

60010685102 Product Introduction:

HARTING Part Number 60010685102(D-Sub Connectors), developed and manufactured by HARTING, distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

60010685102 is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately sales@jinftry.com Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

D-Sub Connectors are widely used electronic connectors whose design is characterized by their unique D-shaped metal housing, a shape that not only provides mechanical support but also ensures the correct orientation and alignment of the connector, preventing misinsertion. The D-Sub connector consists of a series of parallel pins or hole pins that are embedded into a D-shaped housing that itself provides protection for the contacts, but also acts as a grounding path and as part of electromagnetic interference (EMI) and radio frequency (RF) shielding. The design principle of the D-Sub connector is based on the physical contact of the metal contact point, and the corresponding interface is connected through the spring-loaded metal contact to form a stable electrical connection. Its features include high reliability, ease of plugging, and a wide range of pin configuration options for varying density signal transmission needs.

Application

D-Sub Connectors play an important role in many fields such as computers and peripherals, communications and networking, industrial automation, and audio and video. These connectors are often used to realize the exchange of signals and data between devices, for example, in computer peripherals, they are used to connect computer peripherals such as keyboards, mice, printers, etc. In communication devices such as network switching devices, modems, routers, etc., D-Sub connectors are used to transmit data and signals. In industrial automation, they are used to connect PLCS (programmable logic controllers) and other control systems. In addition, the D-Sub connector is also an indispensable component in test and measurement equipment for data acquisition and transmission, as well as the interconnection of in-car networks in automotive electronics.

FAQ about D-Sub Connectors

-

1. What is a D-SUB connector

The name of the D-SUB connector comes from the D-shaped appearance of its plug. It is a double-row cable connector widely used in computer, industrial automation and communication fields. This connector consists of two parts: a plug and a socket. It is connected through pinholes and pins. It can transmit video, audio and digital signals and provide a large number of grounding points.

The D-SUB connector is a compact and versatile connector mainly used to support power, analog, RF or digital signal transmission. It has a variety of models, options and accessories and is a very economical interconnection solution.

-

2. Features of D-SUB connector

1. Easy plugging and unplugging: The D-SUB connector adopts a push-pull plug-in design, which is convenient and fast, and can quickly connect and disconnect the circuit.

2. Reliable contact: The contact of the D-SUB connector is made of high-quality metal material, which is precisely processed and gold-plated, and has good conductivity and long service life.

3. Wear resistance: The contact of D-SUB connector is made of wear-resistant material, which can withstand frequent plugging and unplugging and long-term use, and is not easy to be damaged.

4. Multiple specifications: D-SUB connectors have multiple specifications, suitable for different cables and sockets, and the appropriate specifications can be selected according to actual needs.

5. High reliability: The design of D-SUB connectors focuses on reliability. After strict quality control and testing, it can ensure that there will be no problems such as poor contact or short circuit during use.

-

3. D-SUB connector insulation is poor

Performance: short circuit, insulation resistance is too poor.

Cause: high humidity in the use environment, serious pollution, water or other liquids penetrate into the insulator, etc.

Solution: Improve the use environment, clean the inside of the insulator, and replace the insulator.

-

4. FAQ of D-SUB Connector

D-SUB connector connection is poor

Performance: shell damage, bayonet connector loose or stuck after plugging.

Cause: internal defects of the connector, external force damage.

Solution: Check and repair internal defects of the connector and avoid external force damage.

D-SUB connector oxidation What are the manifestations?

Performance: increased contact resistance.

Cause: environmental factors and current effects.

Solution: Clean and maintain the connector regularly, and use a protective cover to avoid pin exposure.

What problems are caused by deformation of D-SUB connector?

Performance: Affects contact area and stability.

Cause: Mechanical pressure or temperature change.

Solution: Avoid excessive mechanical pressure and check connector status regularly.

Lead free / RoHS Compliant

Lead free / RoHS Compliant