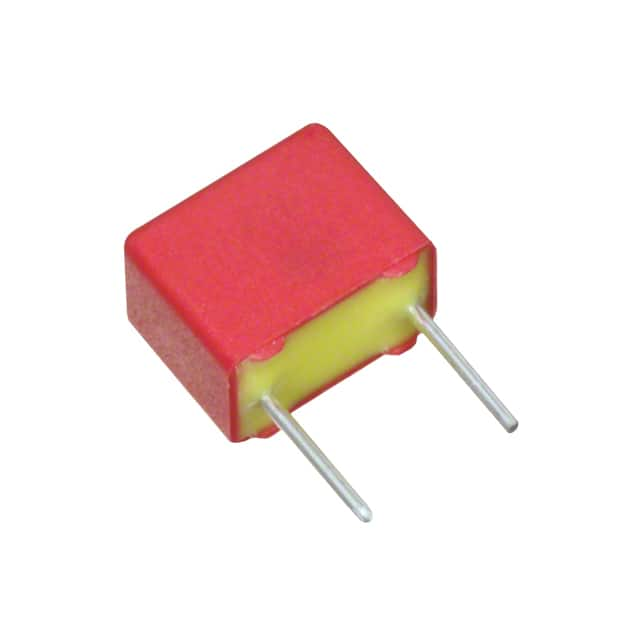

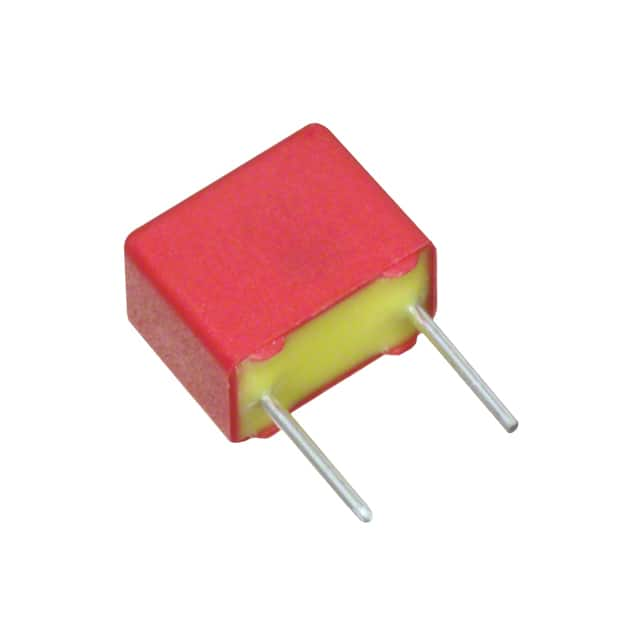

FKP2G004701D00HSSD Product Introduction:

WIMA Part Number FKP2G004701D00HSSD(Film Capacitors), developed and manufactured by WIMA, distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

FKP2G004701D00HSSD is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately sales@jinftry.com Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

Film capacitors are capacitors that use thin film materials as dielectric. This structure mainly consists of two layers of conductive metal foil, sandwiched with a thin film medium, which is usually made of polymer materials such as polyether esters, polypropylene, or polystyrene. The design principle is based on the storage of charges. When voltage is applied to both ends of the capacitor, positive and negative charges accumulate on two layers of metal foil, forming an electric field. Thin film capacitors are renowned for their high stability, low loss factor, and wide operating temperature range, and are particularly suitable for high-frequency circuits. In addition, due to its good self-healing ability, which can self recover after partial breakdown in the dielectric, it has a long service life and high reliability.

Application

Film capacitors are mainly used in multiple industries such as electronics, communication, automotive electronics, and medical equipment. In power electronics equipment, they are widely used in DC link filtering, power supply stabilization, and motor drive circuits to ensure smooth current and stable voltage. In audio devices such as speaker crossover networks, preamplifiers, and power amplifiers, thin film capacitors are favored for their excellent frequency response and low distortion characteristics, which help improve sound quality performance. In addition, thin film capacitors are often used in signal processing and filtering in communication systems, which can effectively remove noise in the signal and improve transmission quality. In the field of automotive electronics, thin film capacitors are used in engine management systems, airbag circuits, and in car entertainment systems to ensure circuit stability and safety. In medical equipment, such as electrocardiogram monitors and pacemakers, the high precision and stability of thin film capacitors make them key components that play an important role in monitoring and treating the health of patients.

FAQ about Film Capacitors

-

1. Is a film capacitor AC or DC?

AC, DC

Film capacitors can be used in both AC and DC circuits. According to the current type, film capacitors can be divided into DC film capacitors and AC film capacitors.

DC film capacitors

DC film capacitors are mainly used in DC circuits and have the following characteristics:

Large capacity: has a higher capacitance.

Low withstand voltage: the withstand voltage value is relatively low.

Polarity: has positive and negative poles.

Application scenarios: commonly used in motor drives, uninterruptible power supplies (UPS), solar inverters, electronic ballasts, small automotive motors, household appliances, etc.

AC film capacitors

AC film capacitors are mainly used in AC circuits and have the following characteristics:

Small capacity: relatively small capacitance.

High withstand voltage: high withstand voltage value.

Pass AC, block DC: conduct electricity in AC circuits, equivalent to open circuits in DC circuits.

Application scenarios: widely used in industrial AC power supplies, asynchronous motor starting and operation, uninterruptible power supplies (UPS) and output filters of photovoltaic inverters, etc.

-

2. What is a paper film capacitor?

Paper film capacitors are actually a conceptual error because "paper film capacitors" are not a standard type of capacitor. Based on the information provided, you may want to ask about paper capacitors and film capacitors.

Paper capacitors

Paper capacitors are capacitors that use paper as a dielectric. It consists of thin paper as the dielectric and aluminum foil as the electrode, which is wound into a cylindrical shape and then impregnated with a shell or epoxy resin. Paper capacitors have the following characteristics:

Low cost: Paper capacitors are usually low-cost and suitable for mass production.

Large loss: Due to its material properties, paper capacitors have large losses.

Application scenarios: Mainly used for bypass, coupling, filtering, etc. in low-frequency circuits.

-

3. How do film capacitors fail?

High working environment temperature, improper selection of working current, exceeding the specified working voltage, harmonic current

The main reasons for film capacitor failure include the following:

High working environment temperature: Film capacitors can work normally in a temperature environment of -40℃~+105℃, but exceeding this range will accelerate thermal aging, resulting in a shortened service life, and even bursting in severe cases.

Improper selection of working current: The current value in the circuit should be less than the current value allowed by the film capacitor, otherwise it will cause the capacitor to heat up, and long-term use will shorten the life, and even burst in severe cases.

Exceeding the specified working voltage: Excessive voltage will cause partial discharge, which will then break down the capacitor and cannot be used.

There are harmonic currents: high-order harmonic currents are superimposed on fundamental currents, resulting in an increase in total current, causing capacitor load overload, internal expansion, and explosion.

Buying inferior capacitors: In order to reduce costs, some manufacturers on the market use low-quality materials to produce capacitors, which greatly reduces the actual withstand voltage and life of such capacitors.

The structural characteristics of film capacitors and the impact of the use environment on their performance:

Film capacitors are usually composed of polypropylene film, aluminum foil and plastic shell. Polypropylene film is sensitive to high temperature, which accelerates its aging and shortens the life of the capacitor. In addition, a humid environment will also cause water vapor to enter the capacitor, affecting its performance.

Lead free / RoHS Compliant

Lead free / RoHS Compliant