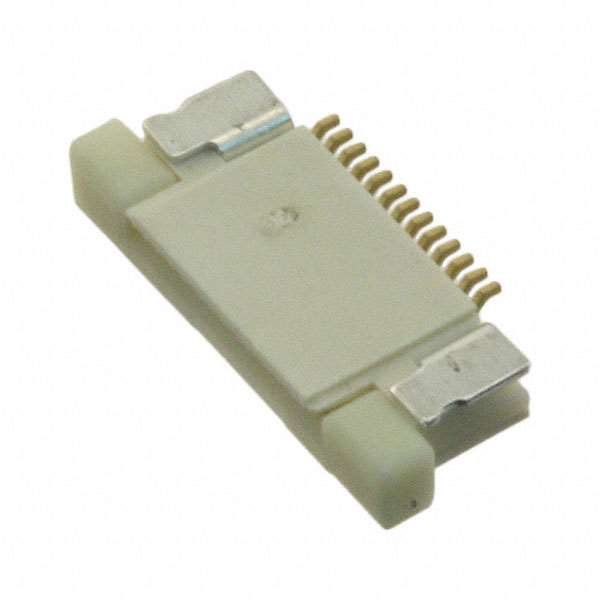

Amphenol ICC (FCI) HLW26R-2C7LF

- HLW26R-2C7LF

- Amphenol ICC (FCI)

- CONN FFC FPC TOP 26POS 1MM R/A

- FFC, FPC (Flat Flexible) Connectors

- HLW26R-2C7LF Datasheet

- -

- -

-

Lead free / RoHS Compliant

Lead free / RoHS Compliant - 4904

- Spot Inventory / Athorized Dstributor / Factory Excess Stock

- 1 year quality assurance 》

- Click to get rates

What is HLW26R-2C7LF

Amphenol ICC (FCI) Part Number HLW26R-2C7LF(FFC, FPC (Flat Flexible) Connectors), developed and manufactured by Amphenol ICC (FCI), distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

HLW26R-2C7LF is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately [email protected] Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

HLW26R-2C7LF Specifications

- Part NumberHLW26R-2C7LF

- CategoryFFC, FPC (Flat Flexible) Connectors

- ManufacturerAmphenol ICC (FCI)

- DescriptionCONN FFC FPC TOP 26POS 1MM R/A

- Package-

- SeriesHLW-R

- Operating Temperature-55°C ~ 85°C

- Mounting TypeThrough Hole, Right Angle

- TerminationKinked Pin

- Contact MaterialPhosphor Bronze

- Contact FinishTin

- Flat Flex TypeFFC, FPC

- Connector/Contact TypeContacts, Top

- Number of Positions26

- Pitch0.039" (1.00mm)

- FFC, FCB Thickness0.30mm

- Height Above Board0.154" (3.90mm)

- Cable End TypeStraight or Tapered

- Housing MaterialPolybutylene Terephthalate (PBT), Glass Filled

- Voltage Rating100V

- Material Flammability RatingUL94 V-0

Application of HLW26R-2C7LF

HLW26R-2C7LF Datasheet

HLW26R-2C7LF Datasheet , HLW-R,-55°C ~ 85°C,Through Hole, Right Angle,Kinked Pin,Phosphor Bronze,Tin,FFC, FPC,Contacts, Top,26,0.039" (1.00mm),0.30mm,0.154" (3.90mm),Straight or Tapered,Polybutylene Terephthalate (PBT), Glass

HLW26R-2C7LF Classification

FFC, FPC (Flat Flexible) Connectors

FAQ about FFC, FPC (Flat Flexible) Connectors

-

1. What is the difference between FFC and FPC connectors?

The main differences between FFC connectors and FPC connectors are in design, application, and performance.

Design Differences

FPC connectors: usually have a multi-layer structure and complex circuit design, are made of conductive materials, and are connected to circuit boards by welding, crimping, etc. FPC connectors are suitable for circuit boards of various shapes and sizes, have extremely high flexibility, and can adapt to different bending and twisting requirements.

FFC connectors: The structure is relatively simple, mainly composed of insulating materials and conductive materials, and are connected to cables by crimping or plugging. FFC connectors are usually used to connect components such as display screens, touch screens, and keyboards. Their flat design makes the cable more stable and reliable during the connection process. -

2. What is an FPC connector?

FPC connector (Flexible Printed Circuit Connector) is an electronic component designed for connecting flexible printed circuit boards (FPC). It has the characteristics of compact structure, light weight, and strong flexibility, and is widely used in electronic products with high space and weight requirements such as mobile phones, laptops, tablets, wearable devices, and camera modules.

The main features of FPC connectors include:

Miniaturization and high-density integration: can save space and simplify wiring procedures, thereby reducing labor costs.

Excellent flexibility: allows flexible twists and turns to adapt to various complex connection requirements.

Lightweight and low-cost: small size, light weight, easy installation, and strong durability. -

3. What is the difference between flexible PCB and FPC?

There are some differences between flexible PCB (FPC) and flexible circuit board (FPC) in definition and application scenarios.

Definition and materials

Flexible PCB (FPC): Flexible PCB is a type of flexible circuit board, usually made of flexible substrates such as polyimide (PI) or polyester film (PET). This material makes FPC have good flexibility and bendability, can move and stretch freely in three-dimensional space, and is suitable for electronic products that require high density, miniaturization and high reliability.

Flexible circuit board (FPC): Flexible circuit board is a printed circuit board made of polyimide or polyester film as the substrate, with high reliability and excellent flexibility. It has the characteristics of high wiring density, light weight, thin thickness, good bending, and can withstand millions of dynamic bending without damaging the wires.

We are a professional PCB manufacturer who offers comprehensive PCB manufacturing services including: professional Ceramic PCB HDI PCB Heavy Copper PCB High-TG PCB High Speed PCB High Frequency PCB Metal Core PCB PCB fabrication and PCB assembly, providing fast turnaround prototypes for high-end products.

• Prompt Responsiveness

• Guaranteed Quality

• Global Access

• Competitive Market Price

• One-Stop support services of supply chain

Jinftry, Your most trustworthy component supplier, welcome to send us the inquiry, thank you!

Do you have any questions about HLW26R-2C7LF ?

Feel free to contact us: