Vishay Beyschlag/Draloric/BC Components MKP1846410635

- MKP1846410635

- Vishay Beyschlag/Draloric/BC Components

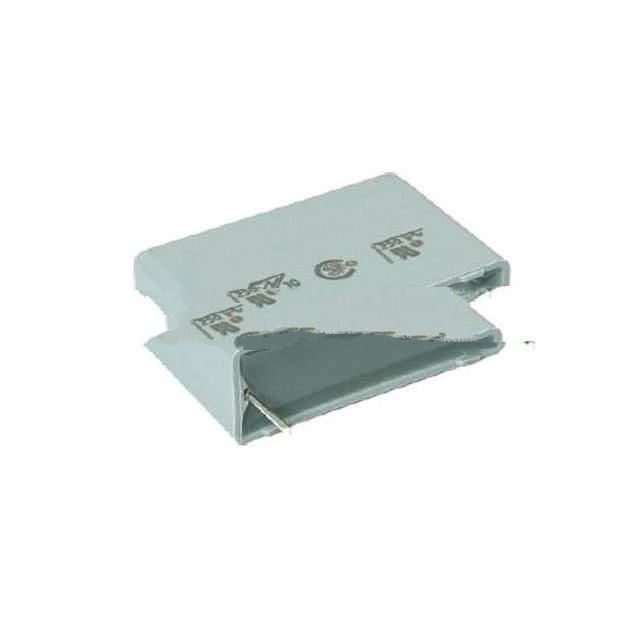

- CAP FILM 0.1UF 10% 630VDC RADIAL

- Film Capacitors

- MKP1846410635 Datasheet

- Radial

- Bulk

-

Lead free / RoHS Compliant

Lead free / RoHS Compliant - 21713

- Spot Inventory / Athorized Dstributor / Factory Excess Stock

- 1 year quality assurance 》

- Click to get rates

What is MKP1846410635

Vishay Beyschlag/Draloric/BC Components Part Number MKP1846410635(Film Capacitors), developed and manufactured by Vishay Beyschlag/Draloric/BC Components, distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

MKP1846410635 is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately [email protected] Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

MKP1846410635 Specifications

- Part NumberMKP1846410635

- CategoryFilm Capacitors

- ManufacturerVishay Beyschlag/Draloric/BC Components

- DescriptionCAP FILM 0.1UF 10% 630VDC RADIAL

- PackageBulk

- SeriesMKP1846

- Features-

- Operating Temperature-55°C ~ 100°C

- Mounting TypeThrough Hole

- Package / CaseRadial

- ApplicationsDC Link, DC Filtering; High Pulse, DV/DT; Snubber

- Tolerance±10%

- Size / Dimension1.043" L x 0.413" W (26.50mm x 10.50mm)

- TerminationPC Pins

- Voltage Rating - AC400V

- Voltage Rating - DC630V

- Lead Spacing0.886\" (22.50mm)

- Ratings-

- Height - Seated (Max)0.728\" (18.50mm)

- Capacitance0.1 µF

- ESR (Equivalent Series Resistance)-

- Dielectric MaterialPolypropylene (PP), Metallized

Application of MKP1846410635

MKP1846410635 Datasheet

MKP1846410635 Datasheet , Bulk,MKP1846,-55°C ~ 100°C,Through Hole,Radial,DC Link, DC Filtering; High Pulse, DV/DT; Snubber,±10%,1.043" L x 0.413" W (26.50mm x 10.50mm),PC Pins,400V,630V,0.886\" (22.50mm),0.728\" (18.50mm),0.1

MKP1846410635 Classification

Film Capacitors

FAQ about Film Capacitors

-

1. Is a film capacitor AC or DC?

AC, DC

Film capacitors can be used in both AC and DC circuits. According to the current type, film capacitors can be divided into DC film capacitors and AC film capacitors.

DC film capacitors

DC film capacitors are mainly used in DC circuits and have the following characteristics:

Large capacity: has a higher capacitance.

Low withstand voltage: the withstand voltage value is relatively low.

Polarity: has positive and negative poles.

Application scenarios: commonly used in motor drives, uninterruptible power supplies (UPS), solar inverters, electronic ballasts, small automotive motors, household appliances, etc.

AC film capacitors

AC film capacitors are mainly used in AC circuits and have the following characteristics:

Small capacity: relatively small capacitance.

High withstand voltage: high withstand voltage value.

Pass AC, block DC: conduct electricity in AC circuits, equivalent to open circuits in DC circuits.

Application scenarios: widely used in industrial AC power supplies, asynchronous motor starting and operation, uninterruptible power supplies (UPS) and output filters of photovoltaic inverters, etc. -

2. Will the performance of film capacitors degrade?

Yes

The performance of film capacitors will degrade. The performance degradation of film capacitors is mainly due to their internal structure and material properties.

Reasons for performance degradation

Metal plating oxidation: During the capacitor manufacturing process, there is a trace amount of air between the film layers, which may be ionized under the action of the electric field to produce ozone. Ozone is a strong oxidant that oxidizes the metal plating to produce non-conductive metal oxides, resulting in a reduction in the plate area and a decrease in the capacitor capacity.

Humid air: During the winding process of film capacitors, if the workshop environment is not properly controlled, there will be a large amount of humid air. These humid air will produce air ionization reactions when the capacitor is working, generating ozone, which further causes the capacitor capacity to decay.

Poor quality materials: The film materials used are of poor quality, such as uneven evaporation and defects on the film, which will cause the capacitor capacity to decay.

-

3. What is the difference between foil capacitors and film capacitors?

Electrode materials, structure, and application areas

The main difference between foil capacitors and film capacitors lies in electrode materials, structures, and application areas.

Electrode materials and structures

Foil capacitors: Foil capacitors usually use metal foil as electrodes. This electrode is formed on a plastic film by vacuum evaporation, which is called a metallized film. This structure can save the thickness of the electrode foil, thereby reducing the volume of the capacitor and making it more miniaturized.

Film capacitors: Film capacitors use plastic films as dielectrics. Common plastic films include polyethylene, polypropylene, polystyrene or polycarbonate. These films overlap at both ends and are rolled into a cylinder to form a capacitor.

We are a professional PCB manufacturer who offers comprehensive PCB manufacturing services including: professional Ceramic PCB HDI PCB Heavy Copper PCB High-TG PCB High Speed PCB High Frequency PCB Metal Core PCB PCB fabrication and PCB assembly, providing fast turnaround prototypes for high-end products.

• Prompt Responsiveness

• Guaranteed Quality

• Global Access

• Competitive Market Price

• One-Stop support services of supply chain

Jinftry, Your most trustworthy component supplier, welcome to send us the inquiry, thank you!

Do you have any questions about MKP1846410635 ?

Feel free to contact us: