Vishay Beyschlag/Draloric/BC Components MKT1822533064

- MKT1822533064

- Vishay Beyschlag/Draloric/BC Components

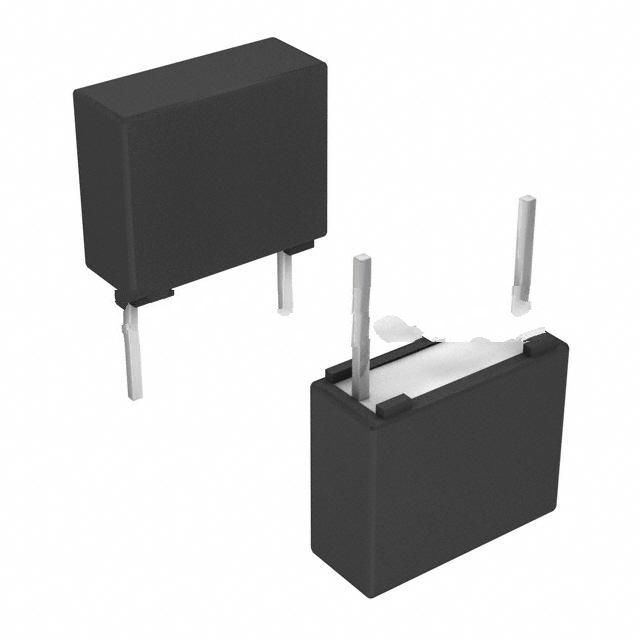

- CAP FILM 3.3UF 5% 63VDC RADIAL

- Film Capacitors

- MKT1822533064 Datasheet

- Radial

- Bulk

-

Lead free / RoHS Compliant

Lead free / RoHS Compliant - 6652

- Spot Inventory / Athorized Dstributor / Factory Excess Stock

- 1 year quality assurance 》

- Click to get rates

What is MKT1822533064

Vishay Beyschlag/Draloric/BC Components Part Number MKT1822533064(Film Capacitors), developed and manufactured by Vishay Beyschlag/Draloric/BC Components, distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

MKT1822533064 is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately [email protected] Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

MKT1822533064 Specifications

- Part NumberMKT1822533064

- CategoryFilm Capacitors

- ManufacturerVishay Beyschlag/Draloric/BC Components

- DescriptionCAP FILM 3.3UF 5% 63VDC RADIAL

- PackageBulk

- SeriesMKT1822

- Features-

- Operating Temperature-55°C ~ 100°C

- Mounting TypeThrough Hole

- Package / CaseRadial

- ApplicationsGeneral Purpose

- Tolerance±5%

- Size / Dimension1.043" L x 0.295" W (26.50mm x 7.50mm)

- TerminationPC Pins

- Voltage Rating - AC40V

- Voltage Rating - DC63V

- Lead Spacing0.886\" (22.50mm)

- Ratings-

- Height - Seated (Max)0.610\" (15.50mm)

- Capacitance3.3 µF

- ESR (Equivalent Series Resistance)-

- Dielectric MaterialPolyester, Metallized

Application of MKT1822533064

MKT1822533064 Datasheet

MKT1822533064 Datasheet , Bulk,MKT1822,-55°C ~ 100°C,Through Hole,Radial,General Purpose,±5%,1.043" L x 0.295" W (26.50mm x 7.50mm),PC Pins,40V,63V,0.886\" (22.50mm),0.610\" (15.50mm),3.3 µF,Polyester, Metallized

MKT1822533064 Classification

Film Capacitors

FAQ about Film Capacitors

-

1. Are film capacitors suitable for audio?

Suitable

Film capacitors are very suitable for audio applications. Film capacitors perform well in audio circuits and have the following advantages:

Non-polarity: Film capacitors have no positive or negative poles, which gives them greater flexibility in circuit design.

High insulation impedance: The insulation impedance of film capacitors is very high, which can effectively reduce leakage current in the circuit and improve the stability of the circuit.

Excellent frequency characteristics: Film capacitors have a wide frequency response and can provide stable capacitance performance in the high and low frequency ranges, which is suitable for various frequency changes in audio circuits.

Low dielectric loss: The dielectric loss of film capacitors is very small, which means that during the transmission of audio signals, less energy is lost and the integrity of the signal is maintained.

Self-healing properties: Film capacitors have self-healing properties and can automatically repair internal defects when they occur, extending their service life. -

2. How do film capacitors fail?

High working environment temperature, improper selection of working current, exceeding the specified working voltage, harmonic current

The main reasons for film capacitor failure include the following:

High working environment temperature: Film capacitors can work normally in a temperature environment of -40℃~+105℃, but exceeding this range will accelerate thermal aging, resulting in a shortened service life, and even bursting in severe cases.

Improper selection of working current: The current value in the circuit should be less than the current value allowed by the film capacitor, otherwise it will cause the capacitor to heat up, and long-term use will shorten the life, and even burst in severe cases.

Exceeding the specified working voltage: Excessive voltage will cause partial discharge, which will then break down the capacitor and cannot be used.

There are harmonic currents: high-order harmonic currents are superimposed on fundamental currents, resulting in an increase in total current, causing capacitor load overload, internal expansion, and explosion.

Buying inferior capacitors: In order to reduce costs, some manufacturers on the market use low-quality materials to produce capacitors, which greatly reduces the actual withstand voltage and life of such capacitors.

The structural characteristics of film capacitors and the impact of the use environment on their performance:

Film capacitors are usually composed of polypropylene film, aluminum foil and plastic shell. Polypropylene film is sensitive to high temperature, which accelerates its aging and shortens the life of the capacitor. In addition, a humid environment will also cause water vapor to enter the capacitor, affecting its performance.

-

3. What is the difference between foil capacitors and film capacitors?

Electrode materials, structure, and application areas

The main difference between foil capacitors and film capacitors lies in electrode materials, structures, and application areas.

Electrode materials and structures

Foil capacitors: Foil capacitors usually use metal foil as electrodes. This electrode is formed on a plastic film by vacuum evaporation, which is called a metallized film. This structure can save the thickness of the electrode foil, thereby reducing the volume of the capacitor and making it more miniaturized.

Film capacitors: Film capacitors use plastic films as dielectrics. Common plastic films include polyethylene, polypropylene, polystyrene or polycarbonate. These films overlap at both ends and are rolled into a cylinder to form a capacitor.

We are a professional PCB manufacturer who offers comprehensive PCB manufacturing services including: professional Ceramic PCB HDI PCB Heavy Copper PCB High-TG PCB High Speed PCB High Frequency PCB Metal Core PCB PCB fabrication and PCB assembly, providing fast turnaround prototypes for high-end products.

• Prompt Responsiveness

• Guaranteed Quality

• Global Access

• Competitive Market Price

• One-Stop support services of supply chain

Jinftry, Your most trustworthy component supplier, welcome to send us the inquiry, thank you!

Do you have any questions about MKT1822533064 ?

Feel free to contact us: