Research and Application of Sodium-ion Batteries-Future Development Trend

Research and Application of Sodium-ion Batteries-Future Development Trend

Sodium-ion batteries (SIBs) are an energy storage technology that has received extensive attention in recent years. The following are the applications and future development trends of sodium-ion batteries:

application:

Power bank: Due to limited lithium resources and rising prices, Na-ion batteries are being researched as a power bank to replace Li-ion batteries.

Renewable energy storage: The output of renewable energy sources such as solar and wind energy fluctuates from time to time. Sodium-ion batteries can be used as intermediate storage devices for these energy sources to ensure the stability of the grid.

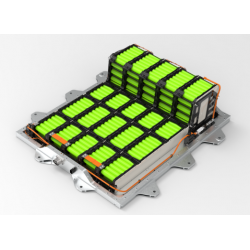

Electric vehicles: Na-ion batteries may be used in some low-cost, short-range electric vehicles, especially in regions where sodium is abundant and lithium is scarce.

Backup and Emergency Power: Where reliable power is required, such as medical equipment, data centers and homes.

Portable Electronics: Although lithium-ion batteries still dominate this area, sodium-ion batteries are likely to be used in certain devices.

Future development trend:

Material innovation: Researchers are looking for new electrode materials and electrolytes to improve the energy density, cycle life, and safety of sodium-ion batteries.

Cost advantage: Since sodium is more abundant in the earth's crust than lithium, sodium-ion batteries have the potential to be a low-cost storage technology.

Structural improvements: The design and manufacturing process of Na-ion batteries will continue to be optimized to improve their performance and reliability.

Sustainability: Sodium-ion batteries may be more environmentally friendly to manufacture and recycle than lithium-ion batteries.

Commercialization process: With the advancement of technology and the demand of the market, it is expected that sodium-ion batteries will gain more market share in different application fields.

Combination with other technologies: Na-ion batteries may be combined with other energy storage technologies such as supercapacitors and flow batteries to provide customized solutions for specific applications.

In summary, Na-ion batteries will likely become an important part of the energy storage field in the next few years due to their abundant raw materials and cost advantages.

How Sodium-Ion Batteries May Challenge Lithium

Rising lithium prices, technological breakthroughs, sodium-ion batteries from cold to recovery:

The working principle of sodium-ion batteries and lithium batteries is very similar, both rely on the movement of metal ions in the battery to achieve charging and discharging. The research on both started almost at the same time more than 50 years ago.

In the first ten years, the product solutions of the two batteries were not balanced enough, either the energy density was too low, that is, too little power in a certain volume, or they were not safe enough, flammable and explosive.

Until 1981, the lithium storage mechanism of graphite was discovered, which means that graphite can be used as the negative electrode and lithium compounds can be used as the positive electrode to construct lithium batteries.

This is a relatively balanced solution with a theoretical upper limit of energy density exceeding 300 Wh/kg, and it is safer than the solution using lithium metal as the negative electrode.

However, due to its large size, sodium ions are more difficult to be embedded in graphite to complete charge and discharge. Its energy density at that time was only one tenth of that of lithium batteries.

As a result, lithium-ion batteries have greater commercial possibilities, and sodium-ion batteries are one step behind.

In 1991, Sony Corporation of Japan successfully applied lithium batteries to video cameras, and the commercialization of lithium batteries was further accelerated, enabling continuous improvement in actual production, and the route of sodium-ion batteries was shelved.

Nearly 20 years later, around 2008, the fortunes of the sodium ion began to reverse. This year, the price of lithium carbonate reached 60,000 yuan/ton, which was the highest point in nearly ten years at that time. Electric vehicles are also on the rise, which will open up a broader market for metal-ion batteries in addition to consumer electronics such as mobile phones and computers.

Under the high lithium price at that time, the advantages of sodium-ion batteries were highlighted: the reserves of sodium were much more than lithium, and the mining cost was low. Salt is a common sodium compound (sodium chloride), and the reserves of sodium chloride in the global ocean up to 4 billion tons.

The demand for reducing the cost of existing products and the superposition of expectations for new markets have brought renewed attention to sodium-ion batteries. According to Chemical Reviews, a comprehensive journal in the field of chemistry in the United States, after 2010, the number of research papers related to sodium-ion batteries rose rapidly from less than 10 per year to dozens, and exceeded 130 in 2013.

After more research, it was discovered that hard carbon could be used as the negative electrode for sodium-ion batteries. Both hard carbon and graphite are simple carbon substances, but their molecular structures are different. Hard carbon has larger voids, which solves the problem that sodium ions are difficult to intercalate into graphite negative electrodes. The energy density of sodium-ion batteries has been improved.

In terms of cathode materials, sodium-ion batteries have gradually developed several main routes:

Prussian positive electrodes, including Prussian white and Prussian blue, which are compounds composed of sodium and ferricyanide;

Layered oxide positive electrode, composed of sodium and metal oxide, the metal can be copper, iron, manganese, nickel, etc.;

Polyanion positive electrode, which is various metal sodium phosphates, such as sodium iron phosphate and sodium vanadium phosphate, etc.

Advantages and disadvantages of sodium-ion batteries compared to lithium-ion batteries:

Sodium-ion batteries (SIBs) and lithium-ion batteries (LIBs) are two common rechargeable batteries in current research and applications. Sodium-ion batteries have specific advantages and disadvantages compared to lithium-ion batteries. Here are their main pros and cons:

Advantages of sodium-ion batteries (SIBs):

Resource abundance: Sodium, a common element in the earth's crust, is more abundant than lithium, so sodium-ion batteries have the potential to be a more economical and sustainable option in the long run.

Cost: Due to the abundance of sodium resources, its raw material cost may be lower than that of lithium resources.

Environmental impact: The extraction and processing of sodium may have a low environmental impact.

Safety: Under certain conditions, sodium-ion batteries may be more stable and safer than lithium-ion batteries.

Disadvantages of sodium-ion batteries (SIBs):

Energy density: Currently, most sodium-ion batteries have low energy density, which means they are relatively larger or heavier to provide the same amount of energy as lithium-ion batteries.

Cycling performance: The cycle stability and lifespan of Na-ion batteries are generally lower than that of Li-ion batteries.

Charging speed: Sodium-ion batteries may charge slower than lithium-ion batteries.

Technology maturity: lithium-ion battery technology is more mature, and there are more products and application examples in the market.

Advantages of lithium-ion batteries (LIBs):

High Energy Density: Lithium-ion batteries typically offer higher energy density, making them the first choice for many high-performance applications such as electric vehicles.

Market Maturity: Due to decades of research and development, lithium-ion battery technology is very mature and widely used in many market segments.

Cycling performance: Under optimized conditions, lithium-ion batteries can provide long-term stability and life.

Lithium-ion batteries (LIBs) disadvantages:

Resource scarcity: Lithium resources are relatively scarce compared to sodium, which may lead to higher costs in the future.

Environmental concerns: Lithium mining and processing can have adverse environmental impacts.

Safety hazard: Under certain conditions, lithium-ion batteries may present a risk of thermal runaway and fire.

Although lithium-ion batteries are still the market leader at present, with the development of technology and the highlight of resource issues, sodium-ion batteries may gain more attention and application in certain application fields.

The reasons why sodium-ion batteries are not currently mass-produced:

Sodium-ion batteries (SIBs) are a research area that has attracted much attention in recent years because sodium is more abundant and cheaper than lithium, and its energy storage potential is promising. However, despite the excellent performance of Na-ion batteries in laboratory research, there are still several technical and economic challenges to achieve large-scale production:

The challenge of electrode materials: The most ideal electrode materials for lithium-ion batteries are not necessarily suitable for sodium-ion batteries. Sodium ions have a larger radius than lithium ions, so the lattice structure of the electrode material needs to be adjusted to accommodate the larger ions. This can lead to reduced storage capacity or stability issues.

Energy Density: The energy density of Na-ion batteries is generally lower compared to existing Li-ion batteries. This means that sodium-ion batteries store less energy for the same weight or volume.

Life and stability: Some sodium-ion batteries will show faster decay during cyclic charge and discharge, which is related to the stability of the electrode material and the interaction between the electrolyte and the electrode.

Safety: Na-ion batteries may face the risk of thermal runaway under certain conditions, which requires further research and optimization to ensure the safety of their applications.

Large-scale production equipment: Because the materials and design of sodium-ion batteries are different from existing lithium-ion batteries, production equipment needs to be adjusted or redesigned, which means a large investment.

Market competition: The existing lithium-ion battery technology is relatively mature and has a strong position in the market. For new technologies to gain market share, they need to demonstrate clear advantages in terms of performance, cost, and security.

Supply chain and ecosystem: The supply chain and related ecosystem of lithium-ion batteries have been relatively well established. Sodium-ion batteries, on the other hand, are still in their infancy and will take time to develop.

Challenging recovery of sodium ions in batteries

Sodium-ion batteries (SIBs) have received increasing attention in the past few years because they use the abundant and cheap element sodium and are considered a promising alternative to lithium-ion batteries. As with all battery technologies, consideration must be given to how they will be recycled and disposed of when they reach the end of their useful life. The following is an analysis of sodium-ion battery recycling:

importance:

Environmental Protection: The chemicals in batteries can be harmful to the environment if not disposed of properly.

Resource recovery: Metals and other valuable materials in batteries can be recycled and reused.

Current challenges:

Technical difficulty: Compared with lithium-ion batteries, the recycling technology of sodium-ion batteries is not mature enough.

Economics: The costs and benefits of recycling need to be balanced. This situation is expected to improve as technology improves and scales up.

Recycling process:

Pretreatment: Batteries are removed from the equipment, sorted and casings removed.

Heat treatment or smelting: Separation of harmful substances from valuable materials by heating.

Chemical treatment: Use chemical solutions to extract metals such as sodium, nickel, cobalt, etc.

Material Recovery: Reuse of extracted metals and other materials.

Future prospects:

Technological innovation: As the market for sodium-ion batteries expands, it is foreseeable that more R&D will be invested in recycling technologies.

Regulatory support: Many countries are implementing strict recycling policies, which will drive the industry to pay more attention to recycling.

suggestion:

Early planning: Battery manufacturers should consider recycling from the design stage, such as choosing materials that are easy to recycle.

Public Education: Enhance consumer education on how to properly dispose and recycle used batteries.

Industry cooperation: Manufacturers, recycling companies, and governments should strengthen cooperation to jointly advance the development of recycling technologies and policies.

In conclusion, the recycling of Na-ion batteries is an important and challenging field. As technologies and policies improve, it is expected that the recycling of such batteries will become more efficient and economical.

edit author:

Jinftry(Hong Kong registered company name: JING FU CAI (HONGKONG) INTERNATIONAL CO., LIMITED) was established in 2013, headquartered in Hong Kong, China, with a branch in Shenzhen, China. It is a global supplier of electronic components and a well-known and competitive electronic product distributor in Asia. Is also an excellent strategic partner of global ODM/OEM/EMS, able to quickly find authentic and traceable electronic components for customers to purchase.