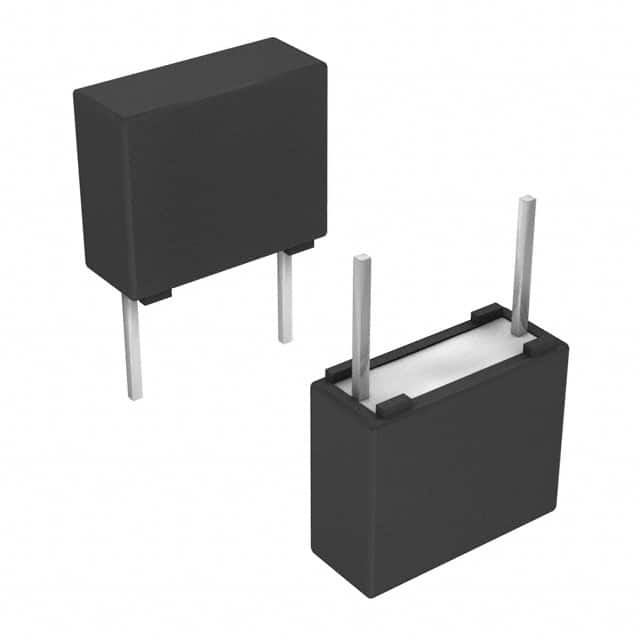

F17724682901 vs BFC241615604

| Part Number |

|

|

| Category | Film Capacitors | Film Capacitors |

| Manufacturer | Vishay Beyschlag/Draloric/BC Components | Vishay Beyschlag/Draloric/BC Components |

| Description | CAP FILM 0.68UF 10% 630VDC RAD | CAP FILM 0.56UF 2% 63VDC RADIAL |

| Package | Tape & Reel (TR) | Tape & Reel (TR) |

| Series | F1772 | MKP416 |

| Features | - | - |

| Operating Temperature | -40°C ~ 110°C | -55°C ~ 85°C |

| Mounting Type | Through Hole | Through Hole |

| Package / Case | Radial | Radial |

| Applications | EMI, RFI Suppression | High Frequency, Switching |

| Tolerance | ±10% | ±2% |

| Size / Dimension | 1.220" L x 0.512" W (31.00mm x 13.00mm) | 0.689" L x 0.276" W (17.50mm x 7.00mm) |

| Termination | PC Pins | PC Pins |

| Voltage Rating - AC | 310V | 25V |

| Voltage Rating - DC | 630V | 63V |

| Lead Spacing | 1.083\" (27.50mm) | 0.591\" (15.00mm) |

| Ratings | X2 | - |

| Height - Seated (Max) | 0.906\" (23.00mm) | 0.532\" (13.50mm) |

| Capacitance | 0.68 µF | 0.56 µF |

| ESR (Equivalent Series Resistance) | - | - |

| Dielectric Material | Polyester, Metallized | Polypropylene (PP), Metallized |

-

1. What are the uses of power film capacitors?

Power film capacitors are widely used in power systems, communication equipment, automotive electronics and household appliances.

Power system

In power systems, power film capacitors are mainly used in high-voltage direct current transmission (HVDC) and reactive power compensation devices. HVDC transmission has the advantages of long transmission distance, low loss and small impact on the environment. Power film capacitors can effectively improve the voltage stability of the system, reduce voltage fluctuations and improve the quality of electric energy. In addition, power film capacitors can also be used in reactive power compensation devices. By adjusting the reactive power in the power grid, the power factor of the power grid can be improved, line loss can be reduced and the utilization rate of electric energy can be improved.

Communication equipment

In communication equipment, power film capacitors are mainly used in devices such as filters, couplers and isolators. Filters are key components in communication equipment, which are used to eliminate noise and interference in signals. Power film capacitors are small in size, light in weight and have good frequency characteristics, which can effectively improve the performance of filters. Couplers and isolators are used for signal transmission and isolation. Power film capacitors can achieve high-frequency and high-isolation coupling and isolation functions to meet the high-performance requirements of communication equipment.

Automotive electronics

In the field of automotive electronics, power film capacitors are used in electronic control units (ECUs), motor controllers, and battery management systems. ECUs are the core components of automotive electronic systems and are responsible for controlling various functions of the car. Power film capacitors can improve their reliability and stability. Motor controllers are key components of electric vehicles and are responsible for controlling the speed and torque of the motor. Power film capacitors can achieve efficient and high-precision motor control functions. Battery management systems are responsible for monitoring and managing battery status. Power film capacitors can improve their accuracy and stability.

Household appliances

In the field of household appliances, power film capacitors are mainly used in home appliances such as air conditioners, refrigerators, and washing machines. These home appliances usually require high power and high-frequency applications. The high-frequency filtering and bypass characteristics of power film capacitors make them perform well in these applications. -

2. Are film capacitors suitable for audio?

Suitable

Film capacitors are very suitable for audio applications. Film capacitors perform well in audio circuits and have the following advantages:

Non-polarity: Film capacitors have no positive or negative poles, which gives them greater flexibility in circuit design.

High insulation impedance: The insulation impedance of film capacitors is very high, which can effectively reduce leakage current in the circuit and improve the stability of the circuit.

Excellent frequency characteristics: Film capacitors have a wide frequency response and can provide stable capacitance performance in the high and low frequency ranges, which is suitable for various frequency changes in audio circuits.

Low dielectric loss: The dielectric loss of film capacitors is very small, which means that during the transmission of audio signals, less energy is lost and the integrity of the signal is maintained.

Self-healing properties: Film capacitors have self-healing properties and can automatically repair internal defects when they occur, extending their service life. -

3. Will the performance of film capacitors degrade?

Yes

The performance of film capacitors will degrade. The performance degradation of film capacitors is mainly due to their internal structure and material properties.

Reasons for performance degradation

Metal plating oxidation: During the capacitor manufacturing process, there is a trace amount of air between the film layers, which may be ionized under the action of the electric field to produce ozone. Ozone is a strong oxidant that oxidizes the metal plating to produce non-conductive metal oxides, resulting in a reduction in the plate area and a decrease in the capacitor capacity.

Humid air: During the winding process of film capacitors, if the workshop environment is not properly controlled, there will be a large amount of humid air. These humid air will produce air ionization reactions when the capacitor is working, generating ozone, which further causes the capacitor capacity to decay.

Poor quality materials: The film materials used are of poor quality, such as uneven evaporation and defects on the film, which will cause the capacitor capacity to decay.

-

4. What are the alternatives to film capacitors?

CL21 capacitors, MPB capacitors, CBB13, CBB81, MMKP82 capacitors

Alternatives to film capacitors mainly include CL21 capacitors, MPB capacitors, CBB13, CBB81 and MMKP82 capacitors. These alternatives have their own advantages and disadvantages in performance and applicable scenarios, and the specific choice depends on specific needs.

CL21 capacitors

CL21 capacitors and CBB22 capacitors can replace each other in applications such as filtering. CL21 capacitors are more stable than CBB22 capacitors under high-frequency conditions, so CL21 capacitors are more preferred in high-frequency circuits. However, CL21 capacitors are more expensive and perform better in high-frequency circuits.

MPB capacitors

MPB capacitors are boxed metallized polypropylene film capacitors with the same core as CBB22 capacitors, but with a plastic shell, which has better resistance to high temperature, moisture and sealing performance. MPB capacitors can replace CBB22 capacitors in high frequency, DC, AC and pulse high current applications, but their prices are relatively high.

CBB13, CBB81 and MMKP82 capacitors

These capacitors have a higher voltage resistance, up to 3000V, and are suitable for applications requiring higher voltages. However, they are also relatively expensive and larger in size.