TLC2554IPW vs ADS8350IRTER

| Part Number |

|

|

| Category | Data Acquisition - Analog to Digital Converters (ADC) | Data Acquisition - Analog to Digital Converters (ADC) |

| Manufacturer | Texas Instruments | Texas Instruments |

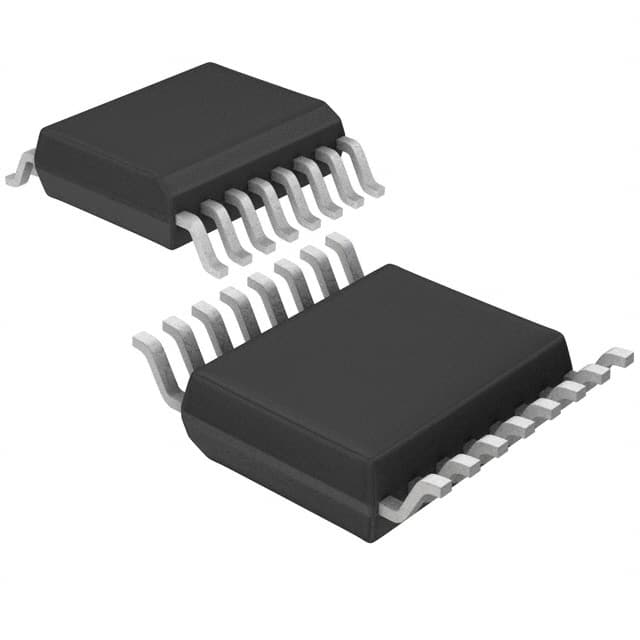

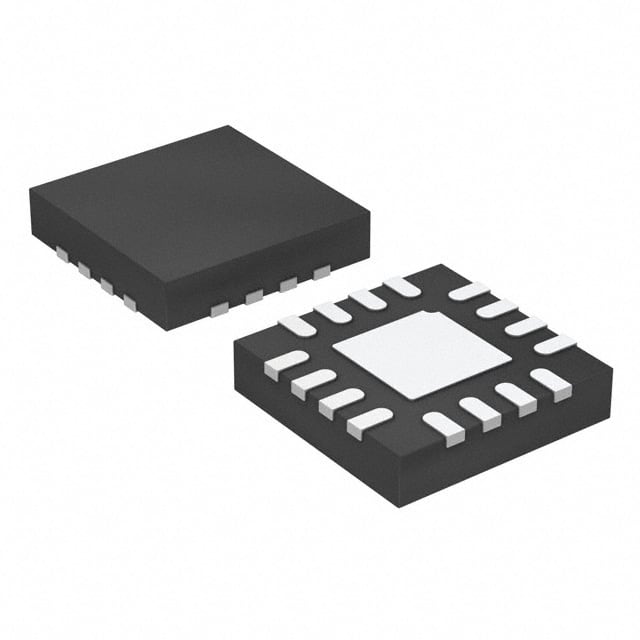

| Description | IC ADC 12BIT SAR 16TSSOP | IC ADC 16BIT SAR 16WQFN |

| Package | Tube | Bulk |

| Series | - | - |

| Features | - | Simultaneous Sampling |

| Operating Temperature | -40°C ~ 85°C | -40°C ~ 125°C |

| Mounting Type | Surface Mount | Surface Mount |

| Package / Case | 16-TSSOP (0.173\", 4.40mm Width) | 16-WFQFN Exposed Pad |

| Supplier Device Package | 16-TSSOP | 16-WQFN (3x3) |

| Reference Type | External, Internal | External |

| Sampling Rate (Per Second) | 400k | 750k |

| Data Interface | SPI | SPI |

| Number of Bits | 12 | 16 |

| Voltage - Supply, Analog | 5V | 5V |

| Voltage - Supply, Digital | 5V | 1.65V ~ 5.25V |

| Number of Inputs | 3, 4 | 2 |

| Input Type | Pseudo-Differential, Single Ended | Pseudo-Differential |

| Configuration | MUX-S/H-ADC | S/H-ADC |

| Ratio - S/H:ADC | 1:1 | 1:1 |

| Number of A/D Converters | 1 | 2 |

| Architecture | SAR | SAR |

-

1. What is ADC for data acquisition?

A data collector is an electronic device used to convert various data (such as barcodes, RFID tags, etc.) into a storable and editable format and transmit it to a computer or system in real time. Data collectors are usually operated using handheld devices (such as inventory counting machines or PDAs) and have functions such as real-time acquisition, automatic storage, instant display, instant feedback, automatic processing, and automatic transmission. They can be widely used in warehouse management, logistics transportation, retail, medical, military and other fields. The main functions of data collectors include data acquisition, real-time data processing, data storage and transmission.

ADC, or analog-to-digital converter, is an electronic device that can convert continuously changing analog signals into discrete digital signals. It is mainly used in data acquisition, signal processing, communication and other fields.

-

2. Why do we need analog-to-digital converters?

The reasons why we need analog-to-digital converters mainly include the following:

Digital system processing: Many computers and electronic devices are digital systems, which are more suitable for processing digital signals. Analog signals are difficult to process in digital systems, and after analog-to-digital conversion, the signals can be represented, stored and processed in digital form.

Noise immunity: Digital signals are more noise-resistant than analog signals. Digital signals can be protected and restored by means such as error correction codes, while analog signals are easily interfered by noise.

Accuracy: Digital signals are more accurate because they can be represented with higher resolution. Analog signals have accuracy limitations, and analog-to-digital conversion can improve the resolution of the signal.

Application scenarios: Analog-to-digital converters are widely used in many fields, including automatic control systems, audio and video processing, sensor interfaces -

3. When is ADC used?

ADC (Analog-to-Digital Converter) is widely used in a variety of scenarios, including but not limited to:

Sensor interface: For example, temperature sensors, pressure sensors, and light sensors, ADC converts analog voltages into digital signals for the use of digital thermometers, temperature control systems, barometers, air pressure sensing systems, light intensity detection and control systems.

Audio signal processing: In microphones, ADC converts analog audio signals into digital signals for digital audio processing, recording, and playback.

Medical equipment: Such as electrocardiograms (ECGs) and oximeters, ADC converts analog signals of ECG signals and blood oxygen saturation into digital signals for heart health monitoring and diagnosis and blood oxygen level monitoring.

Data acquisition system: In various applications that need to collect data from analog signals, ADC is used to convert analog signals into digital signals for storage, processing, and analysis. -

4. What is the principle of analog-to-digital converters?

The working principle of the analog-to-digital converter (ADC) is to convert analog signals into digital signals through four processes: sampling, holding, quantization, and encoding.

The main components of the analog-to-digital converter include samplers and quantizers, which work together to convert continuous analog signals into discrete digital signals. This process requires a reference analog quantity as a standard, and the maximum convertible signal size is usually used as the reference standard. The basic principles of the analog-to-digital converter can be summarized as follows:

Sampling: The analog-to-digital converter first samples the input analog signal through a sampling circuit, that is, discretizes the analog signal on the time axis.

Holding: The sampled signal is held by the holding circuit for the next quantization and encoding process.

Quantization: The quantization process is to divide the amplitude of the sampled and held analog signal into a finite number of le