NXP USA Inc. MPX2010DP

- MPX2010DP

- NXP USA Inc.

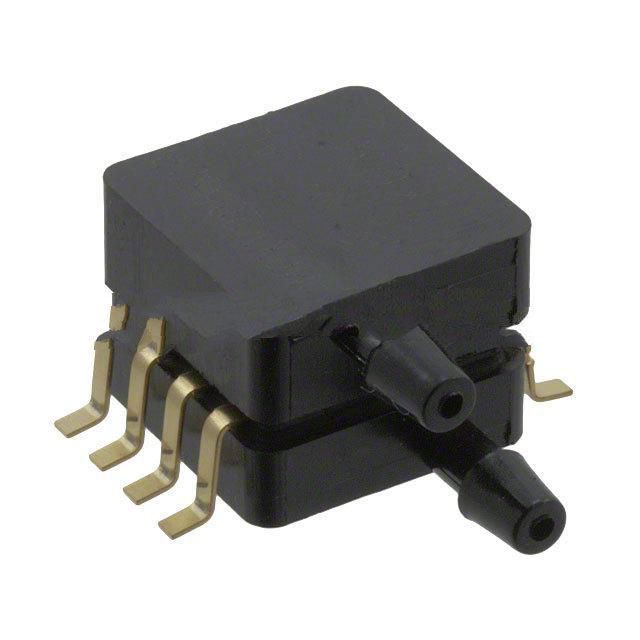

- SENSOR PRESSURE 1.45PSI MAX

- Pressure Sensors, Transducers

- MPX2010DP Datasheet

- 4-SIP Module

- 4-SIP Module

-

Lead free / RoHS Compliant

Lead free / RoHS Compliant - 9265

- Spot Inventory / Athorized Dstributor / Factory Excess Stock

- 1 year quality assurance 》

- Click to get rates

What is MPX2010DP

NXP USA Inc. Part Number MPX2010DP(Pressure Sensors, Transducers), developed and manufactured by NXP USA Inc., distributed globally by Jinftry. We distribute various electronic components from world-renowned brands and provide one-stop services, making us a trusted global electronic component distributor.

MPX2010DP is one of the part numbers distributed by Jinftry, and you can learn about its specifications/configurations, package/case, Datasheet, and other information here. Electronic components are affected by supply and demand, and prices fluctuate frequently. If you have a demand, please do not hesitate to send us an RFQ or email us immediately [email protected] Please inquire about the real-time unit price, Data Code, Lead time, payment terms, and any other information you would like to know. We will do our best to provide you with a quotation and reply as soon as possible.

MPX2010DP Specifications

- Part NumberMPX2010DP

- CategoryPressure Sensors, Transducers

- ManufacturerNXP USA Inc.

- DescriptionSENSOR PRESSURE 1.45PSI MAX

- Package4-SIP Module

- SeriesMPX2010

- FeaturesTemperature Compensated

- Voltage - Supply10 V ~ 16 V

- Operating Temperature-40°C ~ 125°C

- Package / Case4-SIP Module

- Output0 mV ~ 25 mV (10V)

- Accuracy±1%

- Output TypeWheatstone Bridge

- Termination StylePCB

- Pressure TypeDifferential

- Operating Pressure1.45 PSI (10 kPa)

- Port StyleBarbed

- Maximum Pressure10.88 PSI (75 kPa)

- Port SizeMale - 0.19" (4.93mm) Tube, Dual

Application of MPX2010DP

MPX2010DP Datasheet

MPX2010DP Datasheet , 4-SIP Module,MPX2010,Temperature Compensated,10 V ~ 16 V,-40°C ~ 125°C,4-SIP Module,0 mV ~ 25 mV (10V),±1%,Wheatstone Bridge,PCB,Differential,1.45 PSI (10 kPa),Barbed,10.88 PSI (75 kPa),Male - 0.19"

MPX2010DP Classification

Pressure Sensors, Transducers

FAQ about Pressure Sensors, Transducers

-

1. What sensors can be used to measure pressure?

Sensors that can be used to measure pressure mainly include pressure sensors. Pressure sensors can sense pressure signals and convert them into usable electrical signals for output. This type of sensor is usually composed of a pressure sensitive element and a signal processing unit, and is widely used in various industrial automatic control environments, such as water conservancy and hydropower, railway transportation, intelligent buildings, production automatic control, aerospace, military industry, petrochemicals, oil wells, electricity, ships, machine tools, pipelines and other fields.

Application fields of pressure sensors

Industrial field: In industrial production, pressure sensors are used to monitor and control the operating status of various equipment, such as boilers, pipelines, reactors, etc., to ensure production efficiency and product quality, and avoid equipment damage and production accidents.

Medical field: Pressure sensors can accurately measure physiological parameters such as blood pressure and heart rate of patients, and are used in equipment such as ventilators and infusion pumps to ensure patient safety and comfort.

Environmental protection field: Pressure sensors are used in sewage treatment plants, meteorological monitoring, etc. to monitor pipeline pressure conditions, avoid environmental pollution and waste of resources, and provide accurate data for weather forecasts.

Aerospace field: Pressure sensors monitor the cylinder pressure, engine intake pressure and atmospheric pressure of aircraft and spacecraft to ensure the safe and stable operation of aircraft and spacecraft.

What are the four types of pressure sensors?

There are four main types of pressure sensors:

Strain pressure sensor: Strain pressure sensors measure pressure mainly by measuring the strain of elastic elements. Depending on the material, strain elements are divided into metals and semiconductors. When conductors and semiconductor materials are mechanically deformed, their resistance values change.

Piezo-resistive pressure sensor: Piezoresistive pressure sensors are made of piezoresistive effect of single-crystal silicon materials and integrated circuits. When single-crystal silicon materials are subjected to force, the resistivity changes, and an electrical signal proportional to the force change is output through the measuring circuit.

Capacitive pressure sensor: Capacitive pressure sensors use changes in capacitance to measure pressure. When the electrode senses pressure deformation, the capacitance changes, forming an electrical signal output.

Piezoelectric pressure sensor: Piezoelectric pressure sensors use the piezoelectric effect to convert pressure into electrical quantity for measurement. This sensor does not require an external power supply, and directly reflects the pressure by measuring the amount of charge generated, with extremely high sensitivity and fast response time.

-

2. What is the difference between a pressure sensor and a pressure transmitter?

The main differences between pressure sensors and pressure transmitters are working principles, signal processing, and application scenarios.

Working principle

Pressure sensor: The main function of a pressure sensor is to convert a pressure signal into an electrical signal. Common pressure sensors include resistance strain gauges, ceramic pressure sensors, and diffused silicon pressure sensors. These sensors convert pressure changes into electrical signal outputs through piezoresistive or piezoelectric effects.

Pressure transmitter: The pressure transmitter adds a signal conditioning module to the pressure sensor, which can further amplify, convert, and output an electrical signal proportional to the pressure. Transmitters usually have higher accuracy and stability and are suitable for a wider range of pressures.

Signal processing

Pressure sensor: Usually outputs signals directly related to pressure, such as resistance values, capacitance values, etc., which require further processing to obtain useful information.

Pressure transmitter: Directly outputs standard electrical signals, which are easy to process and interpret in the control system and are suitable for various automated control systems.

Application scenarios

Pressure sensor: Widely used in scenarios where real-time pressure monitoring is required, such as industrial automation, medical equipment, etc. Due to its high accuracy and stability, it is also suitable for laboratories, instrumentation, and precision measurement fields.

Pressure transmitter: widely used in process control, energy management and other fields, such as petroleum, chemical, water treatment and other industries. Due to its integrated, intelligent and miniaturized characteristics, it is also suitable for various harsh industrial environments.

In summary, pressure sensors and pressure transmitters have significant differences in principles, signal processing and application scenarios. Users should choose suitable products according to specific needs.

-

3. What is the difference between sensors and actuators?

The main difference between sensors and actuators lies in their functions, design principles and application scenarios.

Function and design principle

Sensor: A sensor is a device that converts various physical quantities (such as temperature, pressure, light intensity, etc.) into easy-to-process electrical signals. Its main function is to detect and collect physical quantities in the environment, and convert these physical quantities into electrical signal output for further processing and analysis.

Actuator: An actuator is a device that converts electrical signals, air pressure, hydraulic pressure and other energies into physical motion. Its main function is to perform corresponding action control according to the received electrical signal, such as controlling the movement of the robot, adjusting the cutting of the machine tool, etc.

Application scenarios

Sensors: Sensors are usually used in areas that require monitoring environmental information, controlling automation equipment, adjusting motion control systems, such as smart homes, aircraft, robots, etc.

Actuators: Actuators are used to adjust control systems, convert energy, complete mechanical work, etc., such as hydraulic pumps driven by electric motors, pneumatic control valves, etc.

We are a professional PCB manufacturer who offers comprehensive PCB manufacturing services including: professional Ceramic PCB HDI PCB Heavy Copper PCB High-TG PCB High Speed PCB High Frequency PCB Metal Core PCB PCB fabrication and PCB assembly, providing fast turnaround prototypes for high-end products.

• Prompt Responsiveness

• Guaranteed Quality

• Global Access

• Competitive Market Price

• One-Stop support services of supply chain

Jinftry, Your most trustworthy component supplier, welcome to send us the inquiry, thank you!

Do you have any questions about MPX2010DP ?

Feel free to contact us: