Classification of IGBT modules, difference between application characteristics and MOSFETs

Classification of IGBT modules, difference between application characteristics and MOSFETs

Both MOSFETs (Metal Oxide Semiconductor Field Effect Transistors) and IGBT (Insulated Gate Bipolar Transistors) are commonly used switching devices in power electronics. They each have their own characteristics and application scenarios, the following are their main differences:

Structure and working principle:

.MOSFET: Based on the metal-oxide-semiconductor structure, the working principle is to use voltage to control the accumulation or depletion of electrons or holes, so as to achieve on and off.

.IGBT: Combining the high input impedance characteristics of MOSFET and the low turn-on voltage drop characteristics of bipolar transistor (BJT), it is a voltage-controlled device.

Conduction characteristics:

.MOSFET: The turn-on voltage drop is related to the size of the device, generally at the volt level.

.IGBT: The turn-on voltage drop is generally between 1.5-3.0V, which is lower than that of high-voltage MOSFETs.

Switching speed:

.MOSFET: Switches very fast.

.IGBT: Relatively slow switching speed, but sufficient for many applications.

Current carrying capacity:

.MOSFET: For lower current applications.

.IGBT: Due to its structure, it can usually handle higher currents and is therefore often used in high power applications.

Voltage level:

.MOSFET: Generally suitable for low voltage applications (tens to hundreds of volts).

.IGBT: Can handle higher voltages, usually in the thousands of volts range.

Loss and Efficiency:

.MOSFET: In low voltage applications, the efficiency may be higher due to its low on-voltage drop.

.IGBT: In high voltage and high current applications, it may be more efficient than high voltage MOSFET due to its lower turn-on voltage drop.

Application fields:

.MOSFET: Typically used in switching power supplies, DC-DC converters and low power applications.

.IGBT: Mainly used in high power applications such as motor drives, renewable energy systems and power conversion systems.

cost:

.MOSFET: Usually cheaper than IGBT for the same voltage and current specifications.

.IGBT: For high power applications, although the unit cost may be higher, the total system cost may be lower due to its performance advantages.

Temperature characteristics:

.MOSFET: At high temperature, the on-resistance increases.

.IGBT: At high temperature, the turn-on voltage will be slightly reduced and have better temperature characteristics.

Driver complexity:

.MOSFET: relatively simple to drive due to its pure voltage drive characteristics.

.IGBT: Although it is also voltage-driven, due to its structure, more protection strategies need to be considered, such as over-current and short-circuit protection.

Introduction to IGBTs:

An IGBT (Insulated Gate Bipolar Transistor) is a semiconductor switching device that combines the high input impedance of a MOSFET with the high current drive capability of a bipolar transistor (BJT). Because it combines the advantages of these two devices, IGBTs are widely used in medium and high power applications.

Classification of IGBTs:

Classified by voltage level:

Low voltage IGBT: typically 600V

Medium voltage IGBT: e.g. 1.2kV, 1.7kV

High voltage IGBTs: e.g. 2.5kV, 3.3kV and even higher

Classified by structure:

Punch-through IGBT (Punch-through, PT)

Non-punch-through IGBT (Non-punch-through, NPT)

Classified by application field:

General-purpose IGBTs

drive IGBT

Power IGBT

The use of IGBT:

Due to its high efficiency and high switching frequency, IGBT is widely used in the following fields:

Adjustable speed motor drives: such as electric vehicles, air conditioners, elevator drives, etc.

Renewable energy sources: such as solar inverters, wind generators.

Power transmission and distribution: such as HVDC (High Voltage Direct Current Transmission) and FACTS (Flexible AC Transmission System).

Power supply: such as switching power supply, uninterruptible power supply (UPS).

Induction heating and induction hobs.

Rail transit: such as electric locomotives, urban rail transit, etc.

Characteristics of IGBT:

High input impedance: Since the gate part of the IGBT is insulated, its input impedance is high, which means that less control power is required to drive the IGBT.

Fast Switching Capability: Although an IGBT is not as fast as a MOSFET, it is faster than a normal BJT.

Low turn-on voltage drop: Under high current, the turn-on voltage drop of IGBT is much lower than that of MOSFET.

High current capability: IGBTs have very good current-carrying capabilities, especially compared to their size.

Has the saturation characteristic of BJT: This means that the turn-on voltage of the IGBT hardly increases with the increase of the current when it is saturated.

Need to protect against short circuits: IGBTs are very sensitive to short circuits and therefore require special short circuit protection.

The IGBT has replaced traditional power MOSFETs and BJTs in many applications because it combines the advantages of both devices but also inherits some of their disadvantages,

such as switching losses of MOSFETs and conduction losses of BJTs. But overall, it provides an effective solution for many high power applications.

Top 10 well-known manufacturers of IGBT:

Infineon Technologies: German company, one of the world's leading IGBT producers.

Mitsubishi Electric: A large Japanese company whose IGBT modules are widely used in the industrial field.

Fuji Electric: Another Japanese company and a major provider of IGBT technology.

SEMIKRON: This company is a major producer of power electronic components, especially in the field of IGBTs.

Toshiba: The company has products in many electronics fields, including IGBTs.

ON Semiconductor: This company offers a range of power solutions, including IGBTs.

STMicroelectronics: A large semiconductor company in Europe that produces a variety of power electronic devices, including IGBTs.

Renesas Electronics: A Japanese semiconductor company that also provides IGBT solutions.

Hitachi: Although better known for its large machinery and home appliances, Japan's Hitachi also has a presence in the IGBT space.

ABB: ABB not only contributes to IGBT technology, but also is a leading company in the fields of power and automation technology.

IGBTs (Insulated Gate Bipolar Transistors) combine the high input impedance characteristics of MOSFETs with the high current drive capa

bility of bipolar transistors.

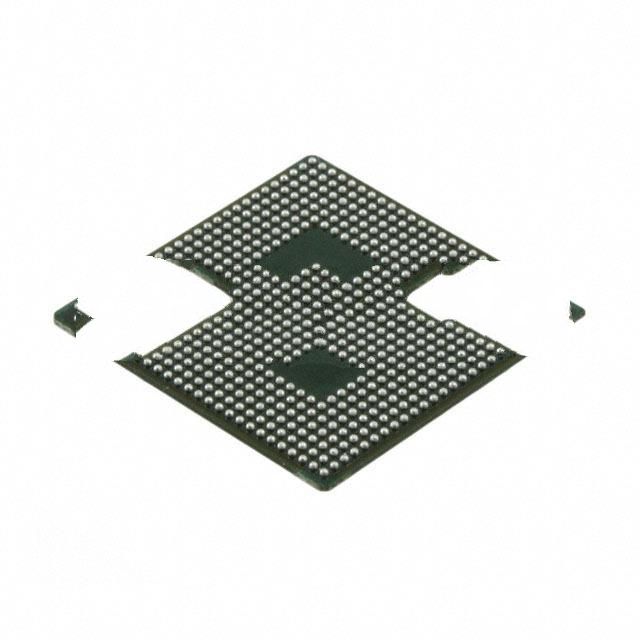

Infineon IGBT inverter module FZ800R12KE3,FZ800R12KE3HOSA1

The structure and materials of IGBT usually use the following main materials:

Silicon (Si): The main semiconductor material of IGBT is silicon. This is because silicon has good semiconducting properties at room temperature and is relatively cheap.

Silicon Carbide (SiC): In recent years, SiC materials have become more widely used in high power and high temperature applications. SiC has higher thermal stability and electric field strength, which can achieve higher switching speed and lower switching loss.

Packaging material: In order to ensure the stable operation and heat dissipation of IGBT, it is usually packaged with plastic, ceramic, aluminum, copper and other materials. For example, to improve heat dissipation efficiency, copper substrates are often used. The enclosure may be made of plastic or metal to provide physical protection and ensure good electrical insulation.

Insulating material: Used to isolate different electrical parts and provide a stable working environment. Commonly used insulating materials include alumina, beryllium oxide, etc.

Wire and solder: Used to connect the internal structure of the IGBT, these materials must have good conductivity and reliability. Commonly used solder materials include silver, tin, copper, etc.

Metal Oxide Semiconductor (MOS) layer: This is the critical part of the IGBT and is used to control the flow of current. This layer is made of a fine metal oxide material, usually silicon.

8 major problems often encountered when using IGBT, and solutions:

An IGBT (Insulated Gate Bipolar Transistor) is a switching device widely used in power electronics applications. When using IGBTs, various problems may be encountered. The following are the 8 major problems and their solutions that are often encountered when using IGBTs:

IGBT overheating during use:

Solution: Make sure the heat sink, cooling fan, or liquid cooling system is working properly. Optimize the thermal design, use proper thermal interface materials, and ensure that the operating conditions of the IGBT are within specified limits.

Oscillation during switching:

Solution: use a proper drive circuit and reduce the inductance of the drive power supply, and add a proper RC snubbing network between the emitter and collector of the IGBT.

Voltage and current spikes during on/off:

Solution: Optimize wiring and ground layout to reduce parasitic inductance, and use fast recovery diodes or other suitable free-wheeling diodes.

Driver circuit problem:

Solution: Make sure the drive circuit is properly powered and follow the manufacturer's guidelines to ensure proper drive voltage and current.

IGBT switching loss is large:

Solution: Select the appropriate IGBT model to ensure its optimal working range in the application. Also consider improving the PWM strategy or adjusting the switching frequency.

Electromagnetic Interference (EMI):

Solution: Use electromagnetic shielding, ground planes, and appropriate filters to reduce interference. Make sure the cables are short and twisted as much as possible to reduce radiation.

Short circuit or overcurrent:

Solution: Use proper protective circuits such as overcurrent sensors and circuit breakers. Implement soft-start and other strategies to avoid initial startup overcurrent.

Longevity and Reliability Issues:

Solution: Make sure that the IGBT works within its specified voltage, current and temperature range. Periodically check and replace aging components such as capacitors and heat sinks.

Jinftry company has the following models in stock (price advantage stock):

2MBI100VA-060-50,APT35GT120JU3,APT40GF120JRD,APT60GF60JU2 ,APTGF165A60D1G ,APTGF180DH60G ,APTGF50DDA120T3G,FZ800R12KE3 ,APT40GF120JRDQ2

2MBI150VA-060-50 ,2MBI150U2A-060-50 ,2MBI200U2A-060-50 ,2MBI200VA-060-50 ,2MBI300U2B-060-50 ,2MBI300VB-060-50 ,2MBI400U2B-060-50 ,2MBI400VB-060-50 ,2MBI600U2E-060 ,2MBI600VE-060

2MBI75U4A-120-50 ,2MBI75VA-120-50 ,2MBI100HB-120-50 ,2MBI100U4A-120-50 ,2MBI100VA-120-50 ,2MBI150VA-120-50 ,2MBI150U4B-120-50 ,2MBI150U4H-120-50 ,2MBI150VB-120-50 ,2MBI150HH-120-50

2MBI200U4B-120-50 ,2MBI200VB-120-50 ,2MBI200U4H-120-50 ,2MBI200VH-120-50 ,2MBI200HH-120-50 ,2MBI225U4N-120-50 ,2MBI225VN-120-50 ,2MBI300U4H-120-50 ,2MBI300VH-120-50 ,

2MBI300U4N-120-50 , 2MBI300VN-120-50 , 2MBI400U4H-120-50 , 2MBI450VH-120-50 , 2MBI450U4N-120-50 ,2MBI450VN-120-50 ,2MBI600VN-120-50 , 2MBI600VE-120-50 , 2MBI600VXA-120E-50 ,

2MBI900VXA-120E-50 ,2MBI900VXA-120P-50 ,2MBI1400VXB-120P-50 ,2MBI75A-170-50 , 2MBI100VA-170-50 , 2MBI100U4H-170-50 , 2MBI150U4H-170-50 , 2MBI150VH-170-50

2MBI200VH-170-50 , 2MBI200U4H-170-50 , 2MBI225U4N-170-50 ,2MBI300U4H-170-50 ,2MBI300U4N-170-50 , 2MBI300VH-170-50 , 2MBI300VN-170-50 , 2MBI400U4H-170-50 , 2MBI450U4N-170-50

2MBI450VN-170-50 , 2MBI550VN-170-50 , 2MBI650VXA-170E-50 , 2MBI1000VXB-170E-50 , 2MBI1400VXB-170P-50 , 6MBP30RTB060 , 6MBP50RA060 , 6MBI50VA-060-50 , 6MBI50VA-120-50

6MBP50TEA060 ,6MBP50TEA120 ,6MBI75U4A-120 , 6MBI75VA-060-50 , 6MBI75VA-120-50 , 6MBP75TEA060 ,6MBP75TEA120 , 6MBP75RA060

6MBI75U4B-120 , 6MBI100VA-060-50 , 6MBI100VA-120-50 , 6MBI100VB-120-50 , 6MBI100U4B-120-50 , 6MBP100TEA060 , 6MBP100TEA120 , 6MBP100RA060 ,

6MBP100RA120 , 6MBI150U4B-120-50 ,6MBI150VB-120-50 ,6MBP150RA060 , 6MBP150RA120 , 6MBI180VB-120-50 , 6MBP200RA060 , 6MBP300RA060 , 7MBR10VKC-120-50 ,

7MBR10SA-120-50 , 7MBR15SA-120-50 ,7MBR15VKC-120-50 ,7MBR15VKD-120-50 , 7MBR25SA-120-50 , 7MBR25VKD-120-50 ,7MBR25VA120A-50 ,7MBP25RA120 , 7MBP25TEA120

7MBP25RU2A120 , 7MBR35VB120A-50 , 7MBR35VKD-120-50 , 7MBR35VA120A-50 ,7MBR50UA-120-50 , 7MBR50VA-060-50 , 7MBR50VB120A-50

7MBP50TEA060 , 7MBP50RA060 , 7MBR50VN-120-50 ,7MBP50TEA120 , 7MBP50RA120, 7MBP50RU2A120 , 7MBP75TEA060 , 7MBR75VB120A-50 , 7MBR75VN-120-50 , 7MBP75TEA120 ,

7MBP75RU2A120 7MBP75RA120 , 7MBP75RA060 , 7MBP100TEA060 ,7MBP100RA060 , 7MBR100VN-120-50 , 7MBR100UB120-50 , 7MBP100VEA120-50 , 7MBR150VN-120-50

7MBP150VEA120-50 , 7MBP200VEA-060-50 , 7MBP200VEA-120-50 , 7MBP100RA120 , 7MBP150TEA060 , 7MBP150RA060 ,7MBP150RA120 , 7MBP200RA060 , 7MBP300RA060

Welcome to consult

edit author:

Jinftry(Hong Kong registered company name: JING FU CAI (HONGKONG) INTERNATIONAL CO., LIMITED) was established in 2013, headquartered in Hong Kong, China, with a branch in Shenzhen, China. It is a global supplier of electronic components and a well-known and competitive electronic product distributor in Asia. Is also an excellent strategic partner of global ODM/OEM/EMS, able to quickly find authentic and traceable electronic components for customers to purchase.