Three-Phase SiC Gate Driver Silicon Carbide Applications

Three-Phase SiC Gate Driver Silicon Carbide Applications

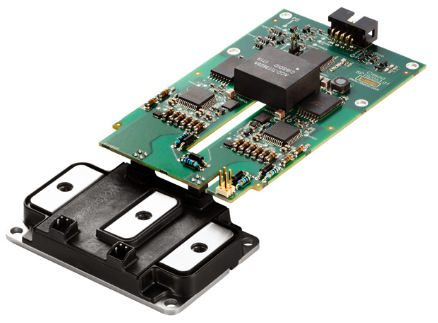

The design of the CXT-PLA3SA12450AA three-phase gate driver is derived from the fully tested and verified CMT-TIT8243 [1, 2] and CMT-TIT0697 [3] single-phase gate driver boards, respectively designed for 62mm 1200V/300A and Fast switching XM3 1200V/450A SiC MOSFET power module (see Figure 4). The three-phase gate driver is optimized to be mounted directly on top of the CXTPLA3SA12450 power module, thanks to a more compact transformer design or slightly adjusted creepage distance settings. The CXT-PLA3SA12450AA gate driver also includes DC bus voltage monitoring functionality. For CMT-TIT8243 and CMT-TIT0697, the maximum operating ambient temperature of the gate driver board is 125°C. All components on the board have been carefully selected and confirmed to ensure operation at this temperature. These designs also rely on CISSOID’s high-temperature gate driver chipsets [4, 5] and power transformer modules optimized for low parasitic capacitance (10pF typical) to minimize power loss at high dv/dt and high operating temperatures. common mode reflected current.

CMT-TIT0697 gate driver board for fast switching XM3 1200V/450A SiC MOSFET power modules

The CXT-PLA3SA12450AA gate driver still has enough headroom to support power module scalability. The module has a total gate charge of 910nC. When the switching frequency is 25KHz, the average gate current is equal to 22.75mA. This is well below the 95mA maximum current capability of the onboard isolated DC-DC converter. Therefore, future power modules with higher gate current capacity and gate charge and higher driving power can be directly driven without modifying the gate driver board. A parallel multi-gate resistor architecture is used to accommodate that the actual maximum dv/dt can be in the range of 10~20 KV/μs (load dependent). The gate driver itself is designed to withstand dv/dt (inductive load) up to 50KV/μs, thus providing sufficient margin in dv/dt robustness.

Gate driver protection function

Gate driver protection features are critical to ensure safe operation of the power module. This is especially true when driving fast-switching SiC MOSFETs. The CXTPLA3SA12450 gate driver provides the following protection features:

Undervoltage lockout protection (UVLO): The CXT-PLA3SA12450AA gate driver monitors the primary and secondary voltages and automatically initiates protection and reports a fault when it is lower than the programmed required voltage.

Anti-overlap protection: Avoid turning on high-side and low-side power circuits at the same time to prevent half-bridge short circuits.

Protection against secondary short circuits: The isolated DC-DC converter can be current limited on a cycle-by-cycle basis, thus preventing the gate driver from any short circuits (for example, gate-source short circuit).

Glitch filter: Suppresses glitches on the input PWM signal, which are often caused by common-mode currents.

Active Miller Clamp (AMC): Bypassing the negative gate resistor after turn-off to protect the power MOSFET from parasitic reflections.

Desaturation Detection: When turned on, checks if the power MOSFET drain-source voltage is below the threshold after the blanking time.

Soft Shutdown: In the event of a fault, the power transistors are slowly turned off to minimize overshoot due to high di/dt.

Advantages of Sic power devices:

Silicon carbide-based power devices offer several key advantages over traditional silicon devices. Its higher voltage and frequency performance enables higher system efficiency, faster switching, lower losses, and better thermal management. Because of this, SiC devices can support smaller, lighter power designs (with higher power density).

SiC-based power devices can operate at junction temperatures up to 200°C (limited only by packaging), reducing cooling requirements and enabling more compact, more reliable and more robust solutions. Existing designs can combine the performance and efficiency advantages of SiC devices without major changes, enabling rapid development turnaround while keeping BOM at a minimum.

Application of SIC:

SiC for electric vehicles: SiC power devices can be used in critical power systems within electric vehicles, including traction inverters, on-board chargers and DC/DC conversion stages. They also provide significant efficiency gains for charging stations.

SiC for industrial power supplies and motor drives: From motors and robots to various other factory automation systems, as well as power supplies for servers and solar conversion systems – a wide range of industrial applications can benefit from SiC devices.

in conclusion

This article proposes a new three-phase 1200V/450A SiC MOSFET smart power module. This new, scalable platform series optimizes the electrical, mechanical and thermal design of power modules and their control drivers, which will help all electric vehicles that want to use SiC power devices to improve driving efficiency and reduce the size and weight of motor drives. OEMs and motor manufacturers, significantly helping reduce time to market for their products.

edit author:

Jinftry(Hong Kong registered company name: JING FU CAI (HONGKONG) INTERNATIONAL CO., LIMITED) is an electronic parts distributor selling latest electronic components including integrated circuits, IC electronics, IC integrated circuits, IGBT, IGBT modules, button battery LR44,discrete te semiconductors, circuit protection, capacitors, resistors, potentiometers, transformers, isolators, crystals , oscillators, resonators, power managers, connectors, switches, relays, sensors, optoelectronic devices, diodes, and various batteries. Welcome to purchase electronic components from brand manufacturers. To view the solutions, you can log in to https://www.jinftry.com/ for inquiries