What is a transformer? What types of transformers are there?

A transformer is a static device that works on the principle of electromagnetic induction. It transfers power from one circuit to another with the desired changes in voltage and current without any change in frequency. Transformers are used in different stages of power generation, transmission, distribution, and consumption of the power grid.

Working principle of transformer:

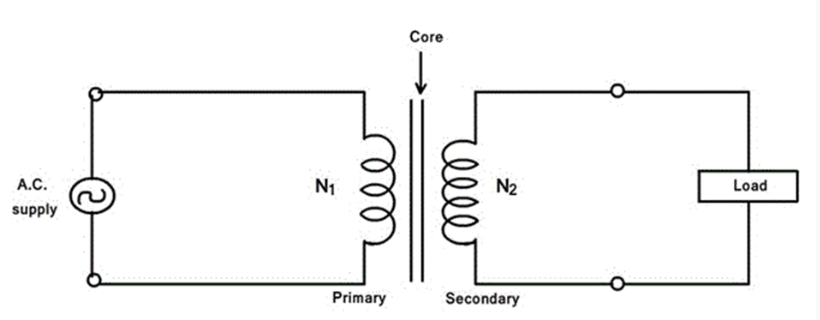

Transformers work on the principle of mutual inductance. When alternating current is applied to a conductor, a changing magnetic field is created around the conductor, creating an electromotive force. This is called self-induced electromotive force. Now, if another conductor is placed in this changing magnetic field, an electromotive force is induced in the second conductor according to Faraday's law of electromagnetic induction. If the circuit of the second conductor is closed, current will flow through it. This is the basic working principle of a transformer.

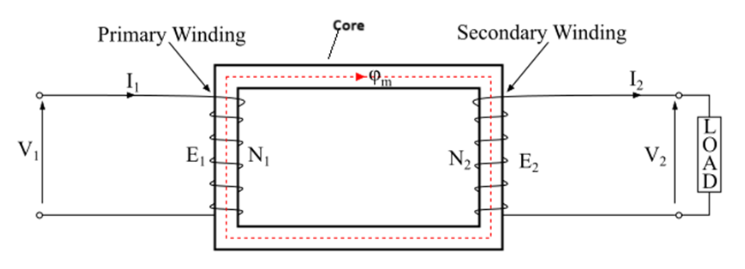

A transformer has two windings or coils. The winding connected to the supply voltage is called the primary winding of the transformer, and the winding connected to the load is called the secondary winding of the transformer. To maximize the flux linkage between the primary and secondary windings, the windings are wound on a low reluctance core.

When AC voltage is applied to the primary of the transformer, an AC flux Ø m is generated in the core and produces EME, E 1 . When the secondary coil is inductively coupled to the primary winding through the magnetic flux Ø m, an electromotive force E2 is generated in the secondary winding. EMF E1 is called the primary EMF, and EMF E2 is called the secondary EMF, which is given by the following formula:

It can be seen from the above relationship that the magnitude of the electromotive force in the primary and secondary windings of the transformer depends on the number of turns of the primary and secondary windings.

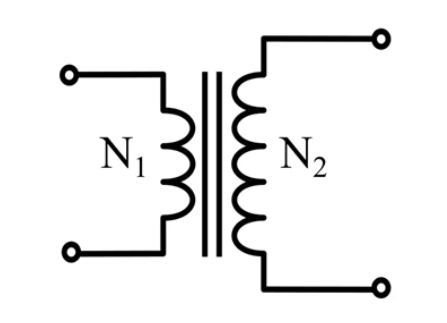

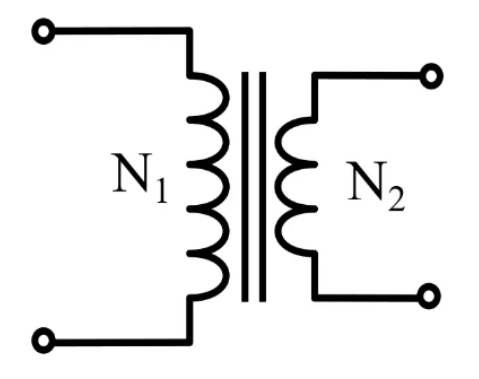

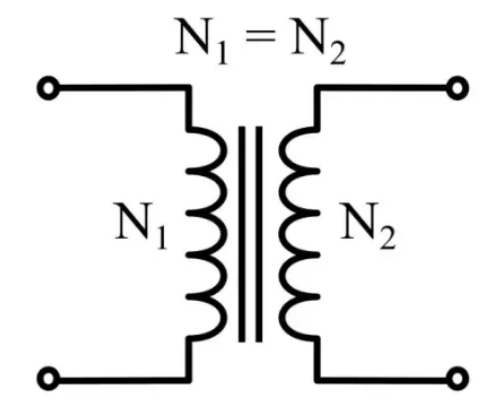

Symbol representation of transformer

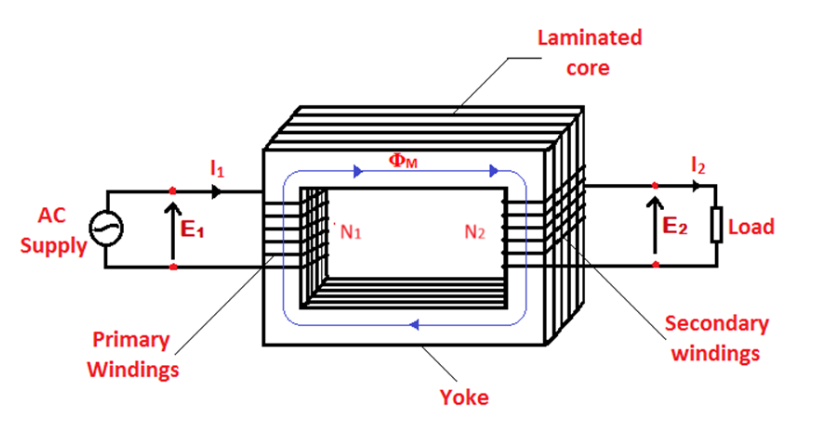

Transformer construction

A transformer has two basic parts:

magnetic core

winding or coil

magnetic core

The core provides a low reluctance path for magnetic flux. Two types of losses occur in the magnetic core. They are hysteresis loss and eddy current loss. These losses are collectively called magnetic losses or iron losses. The core is constructed in such a way that the magnetic losses or iron losses are likely to be low. Typically, the magnetic core is made of high permeability materials such as silicon steel to reduce hysteresis losses.

Eddy currents are generated due to the large width of the material. In order to reduce eddy current losses, the core is constructed with thin laminations. Laminates as thin as 0.5 or 0.7 mm are laid one on top of the other to form a stack, with minimal air gaps between them. In addition, these laminations are insulated using varnish. The core therefore consists of thin laminations of highly magnetic material. The transformer core is composed of laminations of different shapes such as E, L, I, C, and U.

Laminated transformer core

winding or coil

The windings of the transformer are made of electrically conductive material and are wrapped around the limbs of the core. Materials with lower resistivity, such as copper, are preferred because the windings carry both primary and secondary currents. The magnetism of copper enhances the magnetic flux and helps transfer power from the primary to the secondary.

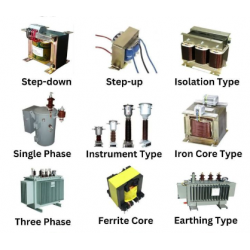

Type of transformer

Transformers can be classified according to various aspects

Based on construction

Based on transformer ratio

Based on core materials

According to application

Based on cooling system

According to supply type

Based on structure: Depending on the way the transformer windings surround the core, transformers can be classified into two types

Iron core transformer: In this type of transformer, the windings are wound around an iron core. The primary and secondary windings are wound on two different branches of the core. It has two cylinders and two horizontal rods forming the frame. The core has excellent magnetic properties and maximum flux linkage between the primary and secondary windings. Different types of core boards, such as E-type, I-type, U-type, and L-type, can be used as needed.

Shell Type Transformer: In a shell type transformer, the iron core surrounds the transformer windings. The primary and secondary windings are wound around the center leg of the core. This type of transformer uses dual magnetic circuits and is suitable for high voltage and low current applications with poor ventilation.

Based on Transformer Ratio: Transformers can be classified based on the number of turns on the primary and secondary side.

Step-up Transformer: A step-up transformer is a transformer that increases the voltage of alternating current (AC). The secondary winding has more turns than the primary winding, which causes the voltage to rise.

For a step-up transformer, N 2 > N 1 , V 2 > V 1 and I 2 < I 1 .

Step-Down Transformer: A step-down transformer is a transformer that reduces the alternating current (AC) voltage. The secondary winding has fewer turns compared to the primary winding. The main function of a step-down transformer is to reduce the voltage while maintaining the same frequency as the input AC.

For a step-down transformer, N 1 > N 2, V 1 > V 2 and I 1 < I 2 .

Based on magnetic core materials: Transformers transfer electrical energy from one circuit to another through electromagnetic induction on a magnetic core. The material used in the core affects the magnetic flux density produced in the core. Therefore, there are many types of transformers depending on the core material used.

Iron core transformer: This type of transformer uses a pile of soft iron plates as the core material. Transformers with iron cores benefit from the excellent magnetic properties of iron. Both the primary and secondary coils are wound around an iron plate, forming a path for the magnetic flux. Iron's excellent electrical conductivity and magnetism ensure minimal magnetic linkage resistance. Therefore, iron core transformers are widely used due to their higher efficiency than air core transformers.

Ferrite core transformer: This type of transformer uses ferrite as the core material. These transformers are used in high frequency applications such as RF circuits and SMPS. The ferrite core ensures minimal losses in high-frequency signals, ensuring overall system efficiency. Ferrite core transformers are available in flexible shapes and sizes and can be customized to specific needs. The most commonly used core is the E-shaped ferrite core.

Air core transformer: This type of transformer uses air as the core material and the primary and secondary windings are not wrapped with any magnetic material. The magnetic flux generated due to the current in the primary winding flows through the air. This type of transformer produces lower mutual inductance compared to iron core and ferrite core transformers.

Depending on the application: Depending on the application, a transformer can be used as a power transformer, distribution transformer, instrument transformer or autotransformer.

Power transformer: A power transformer converts low-voltage, high-current electricity into high-voltage, low-current electricity. They are commonly used in power stations and transmission substations to reduce electricity to the required level suitable for distribution to consumers.

Distribution Transformer: Distribution transformer converts high grid voltage into lower voltage for end users and forms the final stage of the power distribution system. They are single phase or three phase transformers and are available in various sizes to suit various capacities.

Well-known producers such as: Hammond Manufacturing ,Talema Group LLC ..

Transformer: Transformer is also known as isolation transformer. When the primary winding is powered by high voltage and large current, it is used to isolate the secondary winding from the primary winding. The transformer protects measuring instruments or meters connected to the secondary side of the transformer.

For a step-down transformer, N 1 = N 2, V 1 = V 2 and I 1 = I 2

Autotransformer: An autotransformer is a transformer with a single winding that acts as both primary and secondary windings. Due to its single winding configuration, it can transmit power electromagnetically. They are widely used in applications requiring precise voltage control, such as laboratories and test benches.

Based on cooling system: Based on the cooling method used in the transformer, the transformer is divided into:

Dry-type transformer: A dry-type transformer is a transformer that uses air or non-combustible solid insulation instead of liquid as the cooling medium. Unlike oil-immersed transformers, dry-type transformers do not require liquid coolants such as mineral oil. Instead, they rely on natural air convection or forced air circulation to dissipate the heat generated during operation.

Oil-immersed transformer: Oil-immersed transformer, also known as oil-immersed transformer or liquid-filled transformer, is a transformer that uses oil as both a cooling medium and an insulating medium. Oil effectively dissipates heat from the transformer's core and windings while also acting as an electrical insulator between the different components.

Based on the type of power supply: Based on the type of power supply, transformers are divided into single-phase transformers and three-phase transformers.

Single-Phase Transformer: A single-phase transformer is a transformer designed for use with a single-phase alternating current (AC) power supply. In a single-phase system, the voltage alternates in a sinusoidal manner, completing one complete cycle in a given period. The standard residential power supply in many parts of the world is a single-phase system.

Three-Phase Transformer: A three-phase transformer is a transformer designed for use with three-phase alternating current (AC) power. In a three-phase system, three sinusoidal waveforms of current or voltage are offset in time to create a continuous and balanced flow of power. Three-phase power systems are widely used in industrial and commercial applications due to their high efficiency in power generation, transmission and distribution.

edit author:

Jinftry(Hong Kong registered company name: JING FU CAI (HONGKONG) INTERNATIONAL CO., LIMITED) is an electronic parts distributor selling latest electronic components including integrated circuits, IC electronics, IC integrated circuits, IGBT, IGBT modules, button battery LR44,discrete te semiconductors, circuit protection, capacitors, resistors, potentiometers, transformers, isolators, crystals , oscillators, resonators, power managers, connectors, switches, relays, sensors, optoelectronic devices, diodes, and various batteries. Welcome to purchase electronic components from brand manufacturers. To view the solutions, you can log in to https://www.jinftry.com/ for inquiries